Renewed in technical content and functional solutions, Ferrari’s top-of-the-line isodiametric tractors, the “Vega” series, find their most evolved and comprehensive offer in the “Vega 85” models. They are available in four versions: articulated, steering, “DualSteer,” and “Mt,” and boast all the latest technologies developed by Bcs Group.

Technical innovation combined with product diversification has always been one of the prerogatives that have allowed the Bcs Group to play a leading role in the agricultural mechanization sector over the past 80 years. An industrial philosophy that encompasses all commercial areas covered by the Lombard Group, from mowers to single-axle machines to tractors, and that over eight decades has given rise to product lines characterized by technological relevance and functional differentiation, keeping them always one step ahead of the competition. The latest example in this regard is the “Vega” series by Ferrari, developed by drawing heavily from the most advanced solutions developed by the Abbiategrasso Group, but designed based on two versions targeting different commercial markets.

Two versions for two different targets

At the top of the range of the Emilian brand are indeed the “Vega 85” and “Vega K90,” machines that share four configurations: articulated, steering, “DualSteer,” and “Mt,” and most of the functional groups, from the basic structure of the transmission with four ranges and as many gears to the rear lift with a capacity of two thousand and 300 kilograms. However, the technological contents and the engines are different, with the “Vega K90” powered by Kubota “V3800” four-cylinder engines of three liters and 800 cubic centimeters, rated at 75 horsepower, while the “Vega 85” are propelled by Kohler “Kdi 2504 Tcr” four-cylinder units of two liters and 300 cubic centimeters, also delivering 75 horsepower. Same performance, therefore, but combined with different technical contents to allow each tractor to best suit the activities ahead. In this perspective, the “Vega 85” target more structured organizations, those that have the possibility to invest in machines characterized by innovative and advanced solutions aimed at speeding up and simplifying daily operational cycles.

No maintenance downtime

Examples in this regard include the “Self Cleaning System,” which allows reversing the direction of rotation of the cooling fan to eliminate downtime induced by the need to clean the ventilation grilles, and the “Easy Plus” electronic management clutches that automate many of the maneuvers the operator must handle.

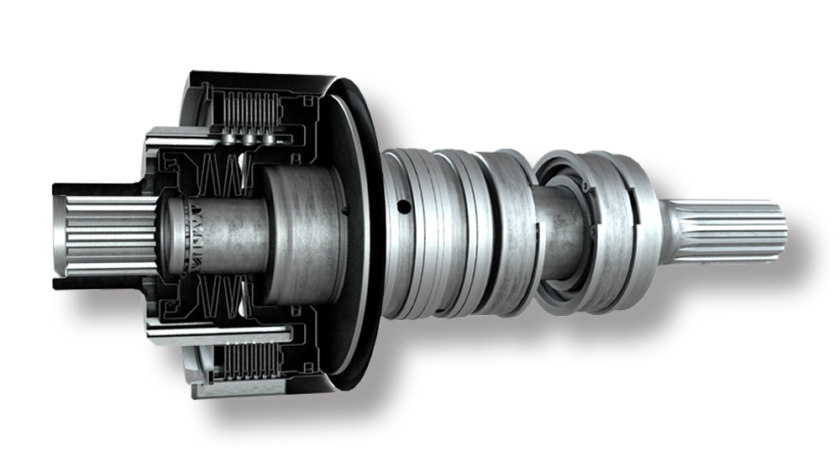

The transmissions, designed and manufactured by Bcs Group, are always mechanical with 16 speeds forward and as many in reverse, but the multiple-disc clutches in oil bath that connect them to their respective engines are electronically managed by dedicated control units that allow changing gear or direction at the push of a button, without having to resort to the classic clutch pedal. Expressed in these terms, one might think that the system is similar to what most traditional tractors offer, but in reality, it is not. In addition to the aforementioned “Power Clutch System” function, the system also provides the operator with the “Smart Brake&Go” function, which allows stopping and restarting the tractor by only using the brake pedal. Also tied to the same digital content is the electro-hydraulic reverser “EasyDrive,” another original patent solution from Bcs Group programmable based on five levels of reactivity and usable without taking hands off the steering wheel. The result is a machine management system that simplifies even the most demanding and burdensome applications, a quality further emphasized if the “Vega 85” are equipped with “Ai-Tractor” technology, essentially an artificial intelligence system that autonomously manages clutch, brakes, reverser, and accelerator to provide responses always adequate to parameters such as, for example, speed, gear ratio, engine speed, and machine inclination.

Four working modes

The functional responses of the system also take into account the operating mode set by the operator by acting on the dashboard menu, which allows selecting four different types of work, each of which involves different and dedicated clutch and reverser engagement rules.

Thanks to this solution, the operator can therefore focus solely on driving and controlling the equipment being used. It should be noted that precisely because of the greater dynamism offered by the “Vega 85” compared to Ferrari’s industry standards, they have also been designed to manage equipment of the same level, a goal pursued through a split hydraulic system that, alongside the 33 and a half liters of oil reserved for onboard services, provides 29 and a half or 51 liters per minute to power the aforementioned rear lift with a maximum capacity of two thousand and 300 kilograms and up to 12 auxiliary distributors, with the rear ones positioned on the mudguards and therefore easy to use. To ensure the cleanliness of the hydraulic oil, there is also a pressure-operated spin-on filter in the cooling circuit, which contributes to maximizing hourly productivity, a goal also pursued by specific proportional joysticks that, in addition to controlling the lift and distributors, allow also to control the engagement and disengagement of the power take-off and the adjustment of the hydraulic flow. The result is therefore a high level of operational comfort, to which the presence of platformed and isolated driving positions also significantly contributes, achieved through silent blocks that, in addition to providing more space for the operator, offer ergonomic and class-leading comfort features induced by a greater longitudinal adjustment stroke of the driver’s seat and by the presence of fully suspended pedals positioned further forward than in the past.

Cabins also in class 4

Also provided on the “Vega 85” model year 2024 are two USB ports to power any electronic devices, as well as the possibility of enclosing the machines through “Space Clima” compartments with six uprights or “Vista Pro” with four uprights, the latter being approved in class 4 to completely isolate the operator from harmful inhalations of dust, aerosols, and vapors during phytosanitary treatments. This is achieved thanks to the presence of two easily replaceable active carbon filters, while a dedicated display on the dashboard allows constant monitoring of internal pressure, internal and external temperatures, and ventilation speed.

Uncompromised maneuverability

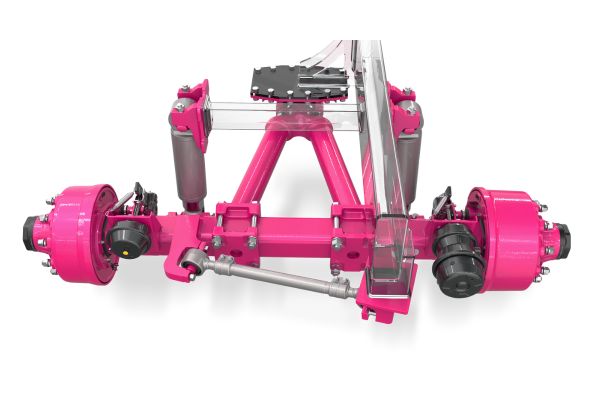

As mentioned, the Ferrari “Vega 85” is also available in “DualSteer” configuration, an original Bcs Group solution aimed at achieving the most advanced maneuverability characteristics in the field of isodiametric tractors. Confirmation comes from the minimum steering radius, which decreases from about three and a half meters of traditional versions to just over two meters and twenty centimeters, thanks to a hydraulic-mechanical system that acts both on the central articulation of the tractor and on the front wheels, allowing the latter to offer turning angles of around 70 degrees.

Smart technology

Ferrari “Vega 85” equipped with “Ai-Tractor” technology offer four different operating modes for four diversified management of clutch engagement modes. The first, called “Forklift,” assimilates the tractor’s behavior to that of an electric or hydrostatic lifter, allowing the operator to perform any stacking operation by slowly and accurately approaching the loads to be lifted by only using the accelerator pedal. Artificial intelligence takes care of managing the clutch and, if necessary, also the brakes and the reverser, leaving the operator the possibility to select different speeds.

The second operating mode, called “Brake and go,” instead allows controlling forward and reverse movements with the brake pedal and the reverser lever gently and smoothly, leaving the control unit in charge of managing slowdowns, stops, and restarts. When the operator presses the brake pedal, the clutch opens, causing the tractor to advance by inertia at the speed the operator is modulating by using the brakes. Releasing the brake pedal, the tractor resumes its previous speed without jerks, even uphill and with a load applied, in the selected direction.

The other two modes are instead called “Quick reverse” and “Slow reverse,” with the former aimed at forage activities and road and green maintenance, allowing maneuvers to be managed using only the reverser, forgetting about brakes, clutch, and accelerator, which are controlled by artificial intelligence. The same happens in “Slow reverse” mode, but with the difference that when the operator activates the reverser, the tractor stops for a moment before gradually restarting, allowing the operator to potentially act on the steering wheel. This mode is oriented towards tasks that require greater precision, such as exiting a row, cutting grass in the presence of obstacles, or handling heavy loads.

Title: With Ferrari “Vega” series model year 2024 only the best

Translation with ChatGPT