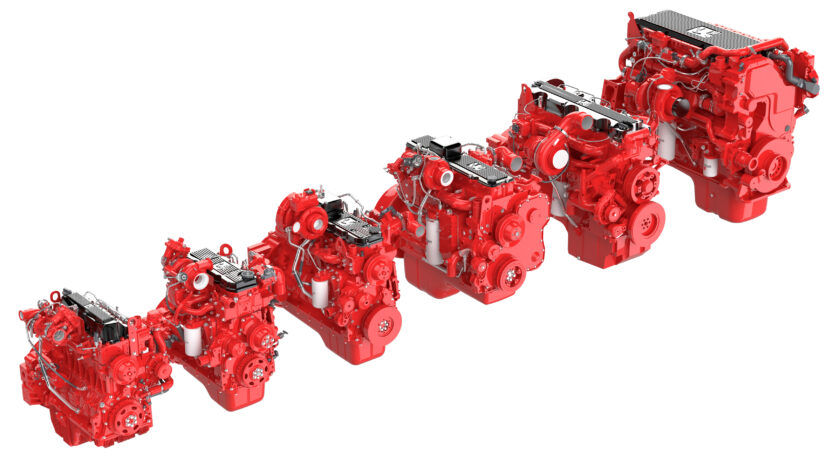

Cummins has produced 115,000 engines in the last five years, with a portion installed in over 14,000 pieces of construction equipment. These units cover a power range from 74 to over 700 horsepower, with displacements ranging from three liters and 800 cubic centimeters to 15 liters. These performance characteristics meet the needs of manufacturers of self-propelled agricultural machinery, as they are paired with compact design mechanics, high efficiency, and considerable ease of installation. These features have been particularly pursued in the development of the power and torque curves of the “Performance” series engines, whose market success is closely tied to the reduced maintenance needs compared to previous models. This aspect significantly contributes to lowering operating costs without hindering the ability to create complete and ready-to-use propulsion packages that also integrate exhaust gas after-treatment systems and radiators. These groups greatly simplify the tuning of powertrains intended to drive agricultural machinery, which is why the Cummins stand at Eima 2024 will feature them prominently, alongside the new “X15 Next Gen” unit, which anticipates the evolutionary steps that Cummins will implement over time across all its engines.

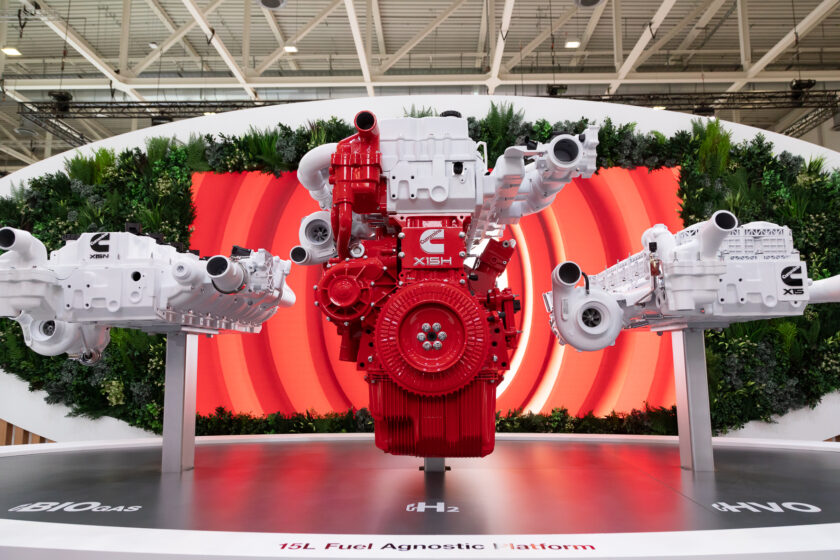

The new unit implements the latest technologies developed by the American company, materialized in what has been termed the “Helm” platform. This is essentially a modular engine block that can be paired with different cylinder heads and various fuel systems, allowing it to operate with a wide range of fuels while maintaining its fundamental characteristics. From diesel to natural gas to hydrogen, this multifuel approach aims to maximize the operational capabilities of future engines without negatively impacting their environmental compatibility.

360 degree compatibility

Cummins had already addressed this approach when it worked to make all its Stage V emission-compliant engines compatible with the use of biofuels like HVO100 and B20.

Regarding performance, it’s important to note that the “X15 Next Gen” boasts superior specifications compared to the previous generation’s 15-liter engines, with a maximum power increase of four percent to 522 kilowatts (700 horsepower) and a torque increase of 15 percent to 3,200 newton-meters. This performance makes the unit ideal for driving large machines, which can fully utilize both the fuel consumption of 180 grams per kilowatt-hour and the extended maintenance intervals of up to 1,000 working hours. Also noteworthy in the Cummins lineup are the “B6.7” units offered with stop-start functionality, an ideal solution for equipping machines that operate at low speeds or in conditions of prolonged inactivity, as they significantly reduce fuel consumption.

Title: With Cummins’ “Next Gen X15” engine a change of pace

Translation with ChatGPT