Each crop has its own specific requirements, and no farm can overlook its budgetary constraints. These priorities, however, often find themselves at odds due to the challenging circumstances facing European agriculture. On one hand, there is a need for highly efficient machinery to speed up operations, while on the other hand, fluctuating commodity prices deter overly costly investments. In this context, it becomes challenging for industrial groups in the agricultural mechanization sector to meet both demands without offering a diversified range of products in terms of technical features, functionalities, and price-performance ratios.

In response, Claas has interpreted this strategy broadly in the combine harvester segment with its flagship “Lexion” series. This product line, structured into four series – “Lexion 8000,” “Lexion 7000,” “Lexion 6000,” and “Lexion 5000,” offers various threshing systems tailored to different application needs. The exclusive hybrid threshing system of the “8000” and “7000” series sets an industry benchmark, while the secondary separation system with straw walkers of the “6000” and “5000” series harks back to a proven tradition.

With such a structure, the “Lexion” range caters to diverse technical and performance differentiations to precisely meet all harvesting requirements. Conventional models aim to meet the application demands of medium-sized farms and those looking to combine high work speeds with complete straw conservation. Hybrid versions primarily address the needs of larger operations and contract organizations working on extensive surfaces due to their high operational capacities.

Four series for 15 basic model

The flagship models of the Claas range offer power ratings up to 790 horsepower, delivered by six-cylinder Man engines with a displacement of 16 liters and 200 cubic centimeters in the “Lexion 8900” model, equipped with the “D42” series. The six-cylinder engines of the “D26” series, with 12 liters and 400 cubic centimeters, are also from Man, delivering 507 to 549 horsepower for the high-end “Lexion 7600” and “Lexion 7700” models, respectively. Mercedes-derived engines power the entry-level and intermediate models, ranging from 408 to 653 horsepower.

Regardless of their origin and displacement, all units comply with Stage V regulations, equipped with cooled EGR systems, DOC catalysts, DPF filters, and SCR after-treatment systems. They interface with workgroups through belt transmissions, acting on reinforced variators connected to the central lubrication system to minimize downtime for maintenance and inspection.

Common to all engines are features like “Dynamic Power” and “Dynamic Cooling,” adjusting engine load and speed according to operator demands to minimize consumption and modulate cooling fan action to minimize energy consumption.

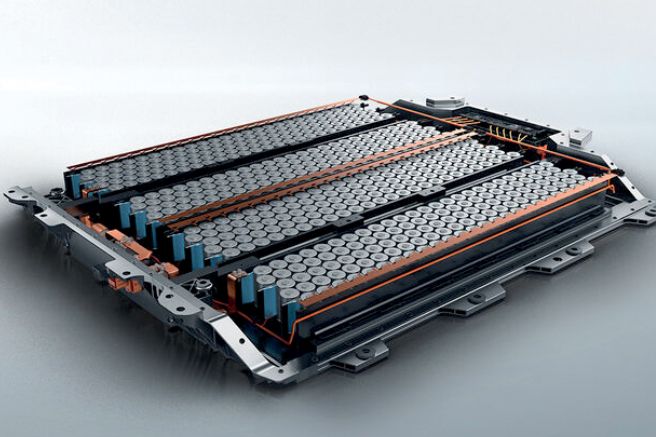

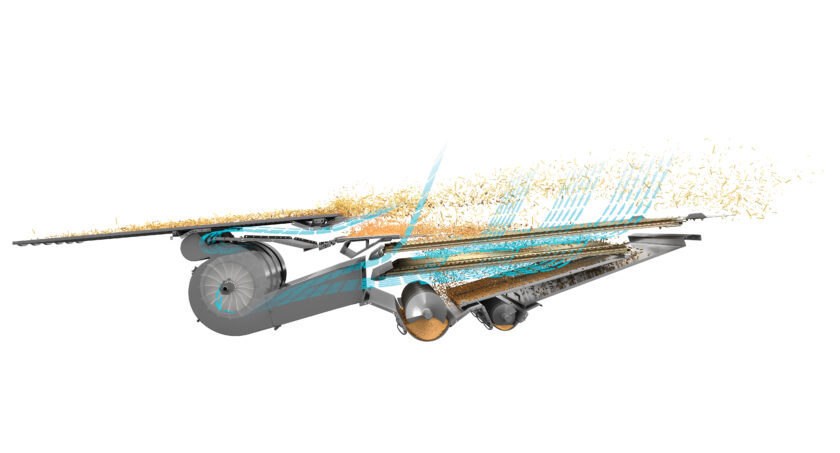

In practical terms, this results in fuel consumption reduction, favoring productive efficiency. This goal is further pursued in the hybrid “Lexion 7000” and “Lexion 8000” series through the renewed “Aps” primary separation system. Renamed “Aps Synflow Hybrid,” it operates with a ten-rod beater, 755-millimeter diameter, with controllable beaters and hydraulically tilting threshing bars for increased treatment intensity under difficult harvesting conditions.

Claas “Lexion” series

Characterized by a width of 1700 millimeters on the “Lexion 8000” and 1420 millimeters on the “Lexion 7000,” the beater also offers a 132-degree wrapping angle and is accompanied by a 600-millimeter diameter thrower that fluidizes and regulates crop access to the “RotoPlus” rotors, characterized by diameters around 600 millimeters and the ability to work automatically at different speeds.

Structured in this way, the system ensures highly effective separation regardless of the type and condition of the harvested product. This objective is further supported by the presence of the proven “Jet Stream” cleaning system, operating via a six- or eight-stage turbine fan, depending on the model, and a double ventilated step for intensive pre-cleaning.

The system provides high-pressure air flow on the sieves, electrically adjustable from the cab, while the “AutoSlope” function adjusts the airflow rate of the cleaning system according to the slope, automatically adapting its action to the harvesting speed.

In these application areas, hybrid “Lexion” combines can also benefit from the “3D” function, automatically compensating for lateral slopes up to twenty percent. Operational process optimization is further enhanced by the “Cemos Automatic” system, acting as an assistant to suggest the most appropriate settings for workgroups based on crop and field conditions and integrating the exclusive “Field Scanner” function.

The “Field Scanner” guides the combine harvester along the crop margin, transmitting functional parameters in real-time to the “Telematics” telemetry system, allowing the vehicle owner to remotely monitor the efficiency of the ongoing work cycle.

For straw quality and preservation, the “Cemos Auto Chopping” system equips the conventional “Lexion 6000” and “Lexion 5000” series, continuously detecting moisture content and straw quantity to automatically adjust the position of the chopper knives and friction bottom according to straw characteristics, optimizing chopping to reduce consumption by up to ten percent compared to similar-class combines, without negatively impacting harvesting efficiency.

To further optimize the secondary separation cycle, a yield meter operates through an impact plate above the grain elevator, measuring the harvested product’s yield in real-time before it passes into bins with capacities ranging from nine thousand to thirteen thousand five hundred liters, topping the category for combines covering power ranges from three hundred to five hundred horsepower.

The “Lexion” range also includes specific models for harvesting on sloping terrain, ensuring productivity comparable to flat terrain operations. These models, named “Lexion 7700 Montana” and “Lexion 5500 Montana,” integrate features such as the Claas hybrid system “Aps Synflow Hybrid” and the renewed conventional system “Aps Synflow Walker,” respectively

Both models feature hydraulic frame adjustment compensating for lateral slopes up to eighteen degrees and longitudinal slopes up to six degrees, optional mechanical all-wheel drive system “Power Trac,” electric front axle differential lock, and the “AutoSlope” cleaning system, automatically optimizing cleaning actions to slope conditions.

Claas “Lexion” series, the tracks come in ten

For those frequently operating on soft or steep terrain, Claas offers a patented track system called “TerraTrac” for several “Lexion” models. These models ensure up to sixty-six percent lower ground pressures compared to conventionally equipped machines, offering increased stability and minimizing slippage without compromising road travel capabilities or rear axle wheel options.

Moreover, to address operator comfort during intensive operating cycles, the “Lexion” range features cabins equipped with modern comfort solutions such as pneumatically suspended seats, electrically adjustable mirrors, cameras for improved visibility, refrigerated compartments for beverages and food storage, and slots for tablets and smartphones. LED projectors ensure maximum visibility on the working area, optionally supplemented with additional lighting systems for evening and nighttime operations.

In summary, the Claas “Lexion” range offers a comprehensive solution catering to diverse harvesting needs, from conventional to hybrid models, with specialized variants for challenging terrains, ensuring high productivity, operational efficiency, and operator comfort.

Title: The “Lexion” series by Claas, four series for 15 basic model

Traslation with ChatGPT