The replacement of engine oil is the first and most important form of maintenance that must be performed to ensure the full functionality of an agricultural or industrial machine. In fact, it is also a contractual obligation imposed by manufacturers to protect their equipment when covered by warranty. However, simple oil replacement, along with the replacement of filter cartridges, is merely a precautionary measure and provides no diagnostic value unless the operation is combined with periodic fluid analyses aimed at detecting the presence of solid or liquid compounds resulting from abnormal wear or leaks.

No unexpected machine downtime

This is supported by the arguments of Texaco technicians, one of the brands within the Chevron family, who state that regularly scheduled fluid analyses can help companies identify potential issues, thereby avoiding costly repairs and unplanned downtime. Nonetheless, many operators remain skeptical, doubting whether the results of these analyses are worth the time, effort, and costs involved. This is an obviously mistaken position, as while an oil change can address a functional issue, it cannot solve it. For instance, if there is a coolant leak or fuel dilution, fresh oil will temporarily mask such contamination, but soon after, these will degrade the fluid’s performance and, consequently, that of the engine. Worse still, if the oil contains wear metals or other solid contaminants from abnormal wear, not only will performance decline while fuel consumption rises, but the entire mechanical system could be at risk.

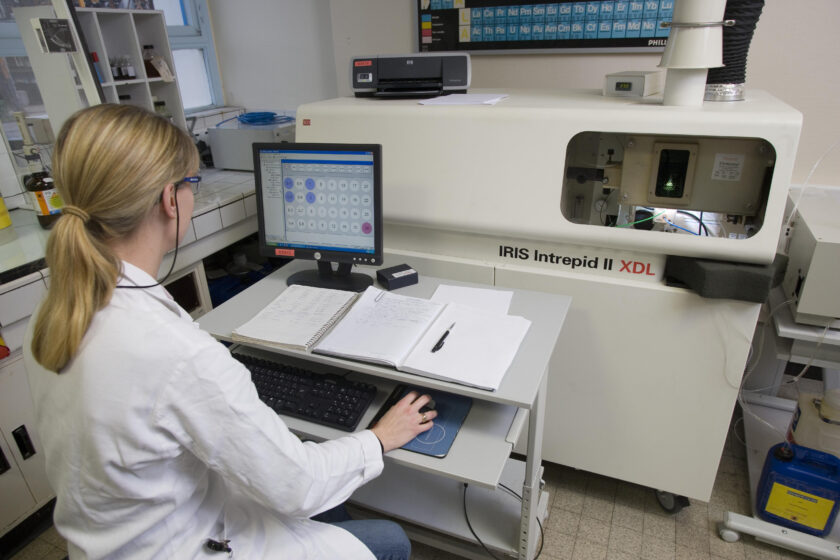

This underscores the need to establish a routine fluid analysis program and make it part of a preventive, predictive, and proactive maintenance strategy. This involves extracting a small amount of lubricant through sampling valves or a pump. The sample should be taken midway through the oil change interval, and once delivered to the laboratory, it will generate a report listing the detected wear metals, contaminants, and physical properties that require monitoring. The easy-to-read information will be accompanied by a list of any corrective actions that need to be taken. It’s worth noting that in addition to better protecting the engines, performing these analyses also creates, over time, a company database on engine health. This can help in planning future investments by precisely identifying which machines need replacement and the causes behind their condition.

Predictive and proactive action

Thus, it is a business management tool that helps maximize the operational life and efficiency of vehicles and equipment, laying the foundation for preventive, predictive, and proactive actions that reduce the costs of unexpected downtime. Additionally, it can be used to support a warranty claim by demonstrating that regular maintenance has been performed, and in the case of a used machine sale, it increases the value of the equipment, serving as concrete proof of its good functional condition. Of course, fluid analyses come with a cost, but this can be minimized by enrolling in Chevron’s “LubeWatch” program, which provides services for multi-vehicle or multi-equipment fleets. In this way, analyses become routine operations, following the same procedures and using the same laboratory, effectively becoming a kind of insurance policy that, over time, offsets the costs of the analyses by minimizing maintenance interventions and unplanned downtime.

A guarantee for evaluating used machines

The fluid analyses conducted by Chevron laboratories prove invaluable when a company is about to purchase a used machine, as they allow for an accurate and objective evaluation of its condition within 24 to 48 hours. All it takes is sending the oil or other lubricants for analysis to one of the two authorized Texaco distributors, which can be found by scanning the QR code published in these pages. This will help create an online “LubeWatch” account and receive sampling kits. After collecting a sample, it should be sent to the laboratory in the pre-addressed envelope provided, and shortly thereafter, the results will be sent via email or accessible online. It’s worth noting that these tests can be conducted on any engine, including stationary ones.

Title: Texaco oils, prevention is better than cure

Translation with ChatGPT