While electric energy seems to be a viable alternative or auxiliary propulsion for cars and trucks, the same cannot be said for agricultural machinery, particularly tractors, due to the wide variability of their applications. As a result, there are currently no satisfactory solutions for achieving zero-emission operation for tractors, nor do battery-based electric drives meet the market’s requirements for acceptable autonomy and operating and refueling times.

Nevertheless, all manufacturers are working on this issue, especially those more environmentally conscious like Steyr. During the 45th edition of the “International Vienna Motor” symposium held in the Austrian capital last April, Steyr presented the first European tractor powered electrically by fuel cells and fully homologated.

700 bar for 12 kilograms of hydrogen

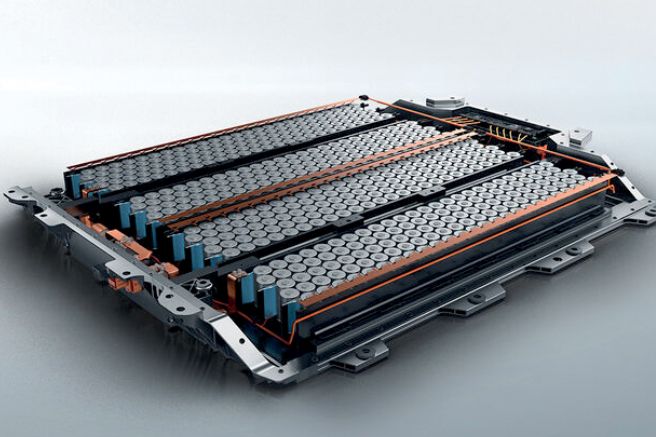

The machine, called “FcTrac” and currently only a prototype, is based on a Steyr “4130 Expert CVT” from which the internal combustion engine and its auxiliary groups have been removed, replacing them with a fuel cell delivering an equivalent power of 136 horsepower at variable voltages between 360 and 560 volts. The cell is powered by a hydrogen tank holding just over 12 kilograms of fuel stored at 700 bar pressure in four carbon fiber tanks located on the roof of the machine, with a total volume of 310 liters. Air is pumped into the cell by a compressor, and from the reaction between hydrogen and oxygen, besides electrical energy, only low-temperature water vapor is produced. The cell operates with an efficiency of over 50 percent, and since its responses to power demands are slow, with about a five-second latency, it is supplemented by a 14-kilowatt capacity battery that acts as a buffer.

46 percent of the machine is new

Overall, the components that differentiate the hydrogen tractor from the traditional one account for about 46 percent of the machine. However, this does not include the continuously variable transmission, a component that facilitates the electric motor’s work but is obviously calibrated differently from the original transmission. Among the newly introduced components are the radiators, whose heat exchange surface has been doubled to allow the cell to always operate at the optimal temperature regardless of the external climate. Without wanting to increase the hood’s size, Steyr’s technicians placed the radiators on the roof, resulting in a height increase of 42 centimeters. The tractor’s mass has also increased by 20 percent, now totaling 7,250 kilograms, and its working autonomy is currently limited to half a day if not used for heavy soil tillage.

Closed-loop productions

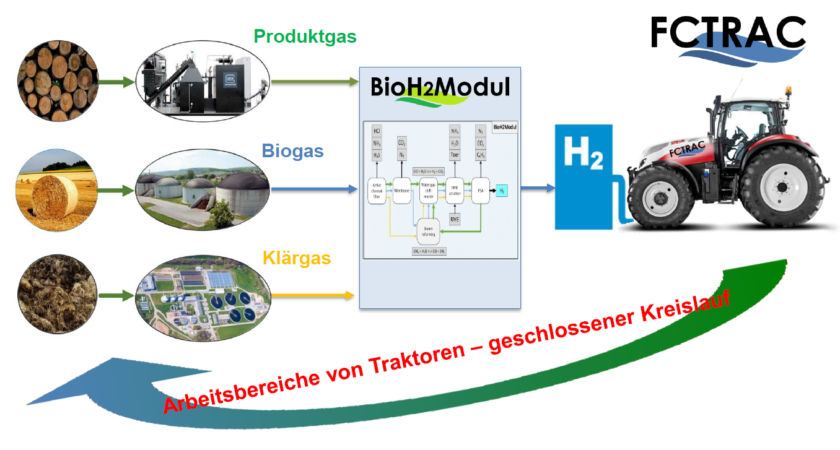

“FcTrac” originates from a project supported with approximately three million euros from a European climate and energy fund, which aims not only to refine the tractor but also to enable farm-scale hydrogen production to compensate for the lack of a distribution network. Specifically, the fuel is produced from wood chips processed at a cogeneration plant in Carinthia, heated up to 800 degrees Celsius. This creates a gas mixture from which hydrogen is separated through various stages, including steam reforming and the water-gas shift reaction. The generation plant and refueling station can be housed in two transport containers, making them compact enough to be installed directly on a farm or in a company’s parking lot.

Title: Steyr “FcTrac”, the future is hydrogen

Translation with ChatGPT