“Tact Von Eller-Ebersteinsche Bga Gbr” is the name of a mixed-type farm operating in northern Germany. In 2011, alongside traditional agricultural production, it started producing electricity from a cogeneration plant powered by a 250-kilowatt Man engine fueled with biogas. The electricity was entirely fed into the grid, while the heat from the engine’s cooling system was used to heat barns and residential buildings. In 2020, due to the positive results from energy production, the plant was expanded with the addition of a second Man engine, this time with a power of 360 kilowatts. After the first 300 hours of break-in, it was decided to lubricate it with Texaco “Hdax 9500 Sae 40” oil, specifically designed for units powered by landfill gas, biogas, anaerobic digestion gas, and sour gases. Thanks to its special composition, this product promised to counteract the buildup of deposits that typically form on key components of engines fueled by high-acidity fuels.

According to Texaco, this would extend the service intervals recommended by Man, which were set at every 400 hours. Contributing to this goal is also a “particularly high retention capacity of the alkaline reserve,” a technical expression that in more common language means lubrication capabilities that remain effective for longer periods compared to traditional oil. Aware of the significant economic benefits from changing oil less frequently, but also of the potential damage from unexpected engine failures, the company decided to extend oil change intervals but subjected the lubricant to a scheduled series of analyses to evaluate its efficiency over time.

Working Hours Extended by Six Times

In collaboration with Texaco, a real field test began, which concluded 2,500 hours later, when the latest analysis indicated the need for a complete oil change rather than just a top-up. In fact, using Texaco “Hdax 9500 Sae 40” extended the working hours by almost six times, allowing the farm to save on five complete oil changes, each requiring the purchase of 23 liters of oil, along with the necessary filters and downtime. After the oil change at 2,500 hours, the test continued up to nearly 7,000 hours of operation, when it was decided to overhaul the engine by sending it to Man for a visual and instrumental inspection of its hot components, including pistons, rings, heads, and cylinders. This inspection also concluded positively, indicating that all examined components met Man’s operational standards and could be reassembled without replacement to allow the engine to resume work.

Specific Coolant as Well

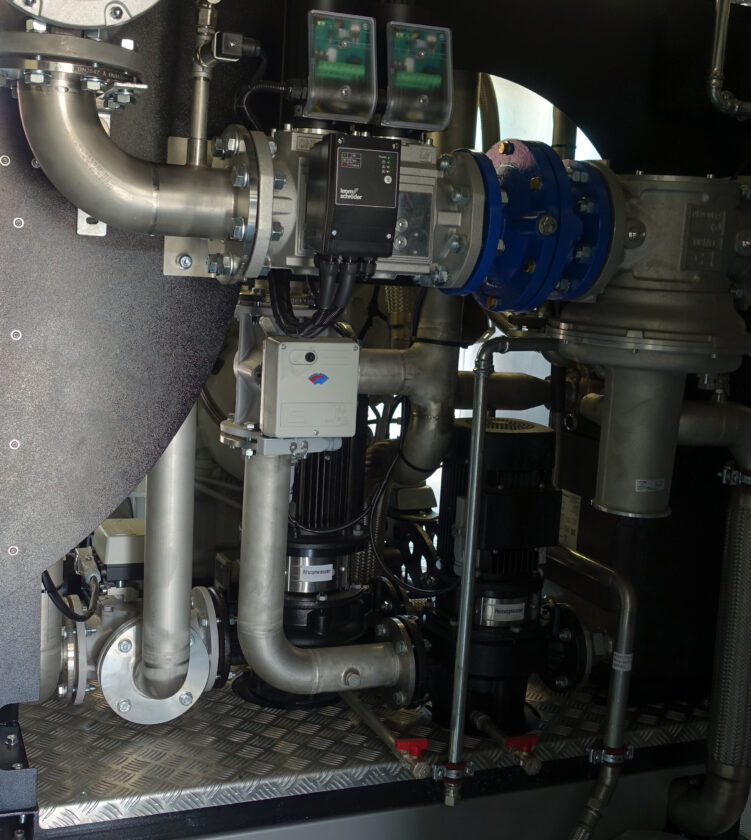

A gas engine typically operates with combustion pressures about four times higher than those in regular diesel engines. Additionally, since gas burns more slowly than diesel, cylinders and piston heads are exposed to high temperatures for longer periods. Proper heat management is therefore crucial to ensure continuous engine operation, and this includes the choice of coolant. The coolant’s job is to remove heat from the engine’s hot parts and dissipate it in the radiator.

There are various types of coolant, with or without silicates. The former provides a protective layer throughout the engine’s cooling system but at the cost of reduced heat transfer. They can also form sludge that, over time, can impair the functionality of pumps, radiators, and thermostats. For these reasons, the Tact Von Eller-Ebersteinsche Bga Gbr farm not only lubricated its 360-kilowatt Man engine with Texaco “Hdax 9500 Sae 40” oil but also cooled it with Texaco “Delo Xlc Antifreeze/Coolant,” a silicate-free coolant specifically designed for high-performance engines operating under difficult conditions. This coolant-antifreeze, by combating internal deposits in radiators and pumps, ensures adequate heat exchange even after many hours of operation. It also helps maintain slightly lower temperatures than those induced by traditional coolants, a particularly important factor for engines running at stationary regimes and fueled by fuels that generate especially high combustion temperatures.

Title: Reduced Engine Maintenance with Texaco Oil

Translation with ChatGPT