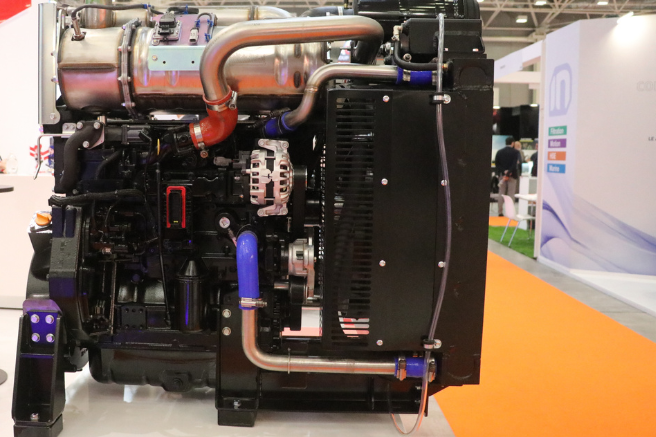

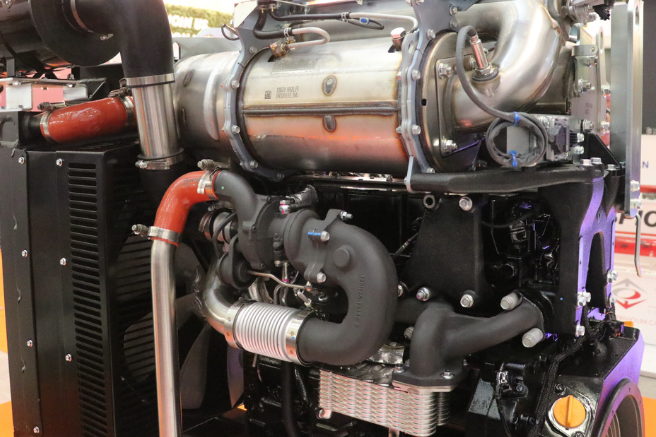

The Yanmar four-cylinder “4Tn101” is not a brand-new product, having been on the market for some time. However, it remains one of the most reliable and versatile engines available, a characteristic reinforced during Eima with the introduction of a “high output” powerpack configuration, calibrated to deliver 105 kilowatts of power (143 horsepower). This addition will expand Yanmar Italia’s commercial offering. Compact in size and thoroughly tested in terms of its thermal group, the engine is presented as a powerpack complete with all necessary accessories and services for operation—an autonomous energy unit that is easy to install on any agricultural or industrial machine and can be calibrated for specific applications.

The powerpack configuration also includes integrated services such as a cooling radiator and post-treatment systems to ensure compliance with Stage V regulations while preserving the compact size and dimensions of the unit. The DOC catalyst, particulate filter, and SCR system are integrated into a single block along with the urea tank, designed to be installed on the machine in a non-intrusive manner, blending seamlessly into the machine’s layout. With this offering, Yanmar aims to further expand its market presence, emphasizing the balanced characteristics of an engine that delivers high performance without overburdening thermal or mechanical stress, reaffirming the robustness and reliability for which the brand is known.

Specifications of the “4Tn101”

It is worth noting that the “4Tn101” positions itself within the current market segment for engines with a unitary displacement of one liter, defined by a bore of 101 millimeters and a stroke of 120 millimeters, resulting in a stroke-to-bore ratio average for its segment, close to 1.2.

Power Range: 104 to 143 Horsepower

The total displacement is 3.844 liters, and in its current calibrations, it spans a power range from 104 to 143 horsepower. It features a direct fuel injection system and a single turbocharger with an intercooler. The engine meets the torque demands of off-road applications well, delivering 550 Newton-meters at its maximum calibration, achieved at 1,500 RPM. It also provides 455 Newton-meters—82% of maximum torque—at just 1,000 RPM. This creates an effective operating range exceeding 700 RPM between the peak torque and power regimes, making the engine particularly suited for mission profiles requiring high flexibility.

Specific Units for Pump Applications

Alongside the “4Tn101,” the “4Tnv98C” unit was also showcased at the booth, with a slightly lower rating of 52 kilowatts (70 horsepower), also in powerpack configuration. Among its applications, it is notably suited for use in pump systems. Yanmar’s range of four-cylinder engines is well-equipped to meet the specific demands of this segment, including the ability to operate autonomously without direct supervision. This is achieved through dedicated technical solutions, such as a sophisticated DPF regeneration system, three-stage emission management units, and the capability to operate for at least 6,000 hours without maintenance, all while maintaining emissions aligned with Stage V regulations.

Notably, both units are compatible with “HVO” fuels, derived from hydrotreated vegetable oils and compliant with the EN15940 standard.