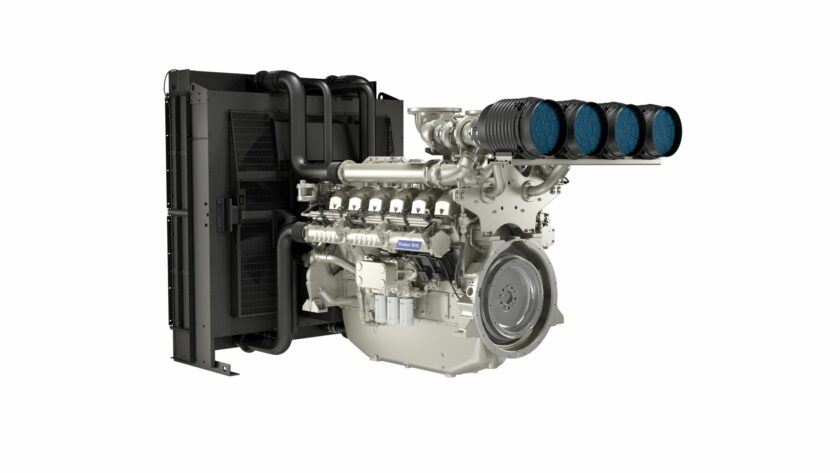

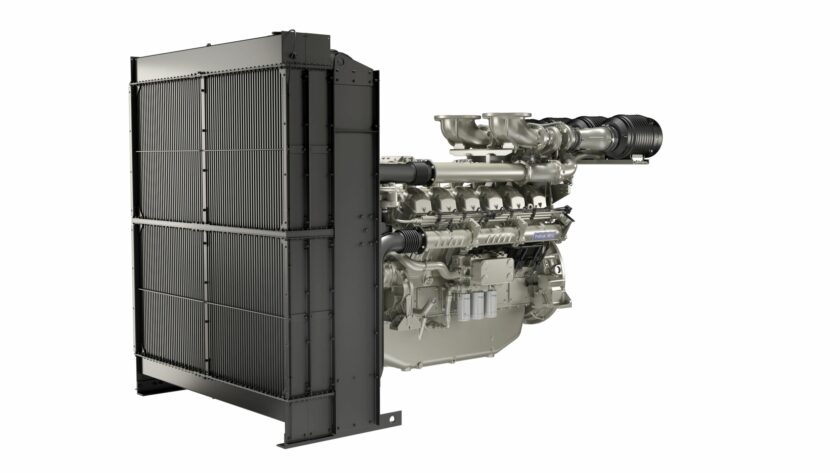

It is unlikely to find space in the agricultural sector, but secret agent 007 teaches us to “never say never,” and in any case, the machine deserves to be showcased. It is a new genset powered by a 12-cylinder engine labeled “5012,” which is at the top of both the Perkins “5000” series and the entire production range of the company. Specifically designed for power generation applications, the unit can deliver power outputs ranging from 1,275 to 1,710 kilovolt-amperes in primary generation applications at 50 hertz and from 1,250 to 1,500 kilowatts as a critical load generation system at 60 hertz.

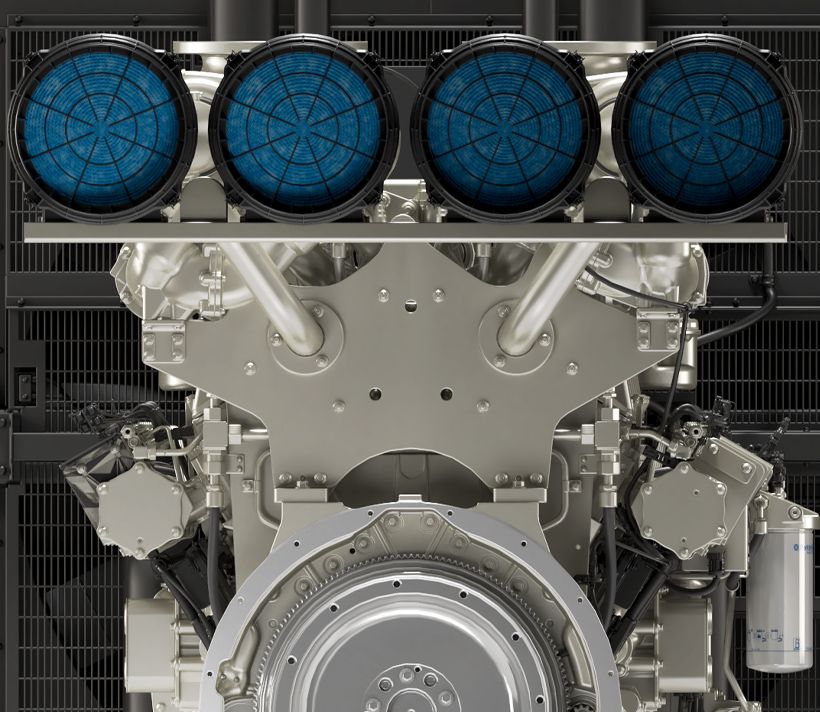

12-Cylinder V-Configuration

The engine introduces a new architecture to the series compared to the previously characterized six and eight-cylinder inline engines, as it is organized with two banks of six cylinders in a V-configuration, creating a compact 12-cylinder engine despite a total displacement of 45.84 liters. This volume is achieved with cylinders having a bore of 160 millimeters and a stroke of 190 millimeters, with a compression ratio of almost 14:1. The architecture features a length of less than four meters, a width of 2.2 meters, and a height of 2.613 meters, with a weight of 5,860 kilograms that produces a maximum power output of 1,638 kilowatts, or 2,227 horsepower, at 1,500 rpm.

Low Inertia Turbochargers

Beyond performance, the new “5012” is also designed to offer high operational efficiency, minimize fuel consumption, and comply with emission regulations, ensuring the possibility of being fueled with various types of fuels, including up to 20% biodiesel or 100% hydrotreated vegetable oil (HVO). To reduce response transients to load variations, the unit is equipped with a pair of small turbochargers, one for each bank, assisted by exhaust manifolds designed to optimize gas flow towards the turbines. Another distinctive feature of the new engine is the low-pressure fuel supply system, developed specifically for the “5000” series. It can tolerate significant variations in fuel quality, ensuring reliable operation even in adverse conditions.

The system operates with direct injection using electronically controlled injectors, allowing the engine to adapt to a wide range of ambient temperatures and altitudes without compromising performance. Along with the advanced turbocharger technology, these injectors help optimize delivery and fuel consumption. Finally, it is worth mentioning the presence of an electric fuel supply pump and premium fuel and oil filters, which guarantee an extended maintenance interval of up to 500 hours or two years.

Title: Perkins “5012”, top of the range for power generation

Translation with ChatGPT