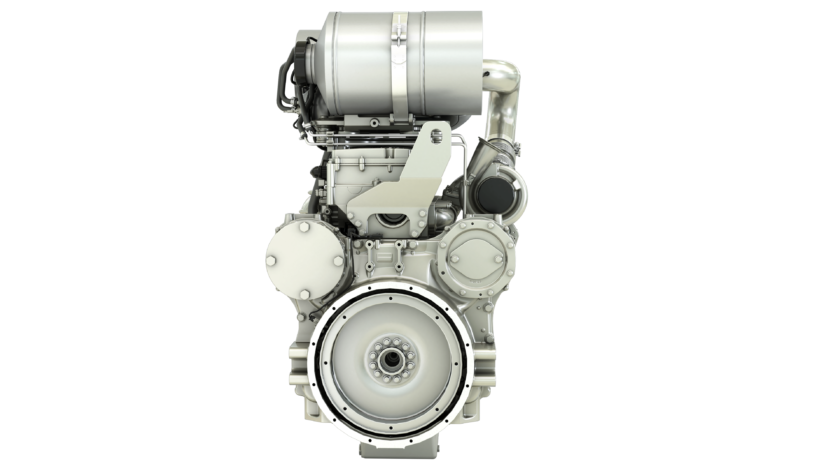

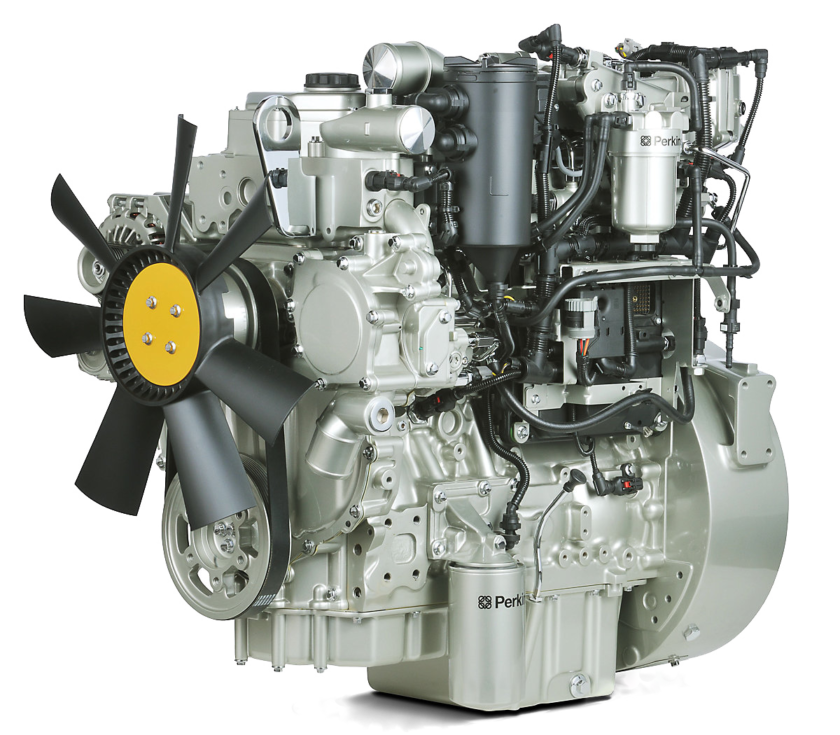

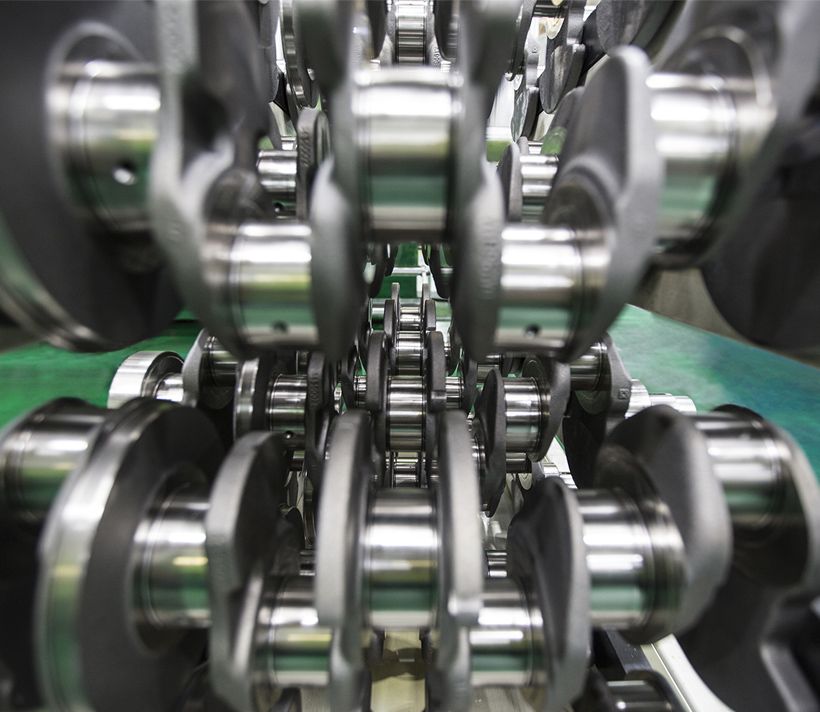

The engine industry is undergoing a crucial transformation phase, aimed at reducing emissions and improving energy efficiency. In this context, Perkins has introduced the development of the new “2600” series, a 13-liter platform designed to provide power density, torque, and efficiency that align with the most stringent design and operational constraints imposed by the agricultural mechanization sector, as well as more broadly by construction and industrial applications. The unit, shown for the first time at Eima 2024 and set to be included in Perkins’ offerings starting in 2026, will exhibit a power range between 240 and 515 kilowatts (450 to 690 horsepower), with peak torques around 3,200 Newton-meters. It will replace four different engine blocks with displacements ranging from 12.5 to 18 liters. This rationalization is made possible by designing all components from a blank slate, allowing for maximum cylinder pressure peaks of 240 bar, achieved through a common rail fuel system operating at 2,500 bar, combined with compression ratios of 18 to 1.

It will replace four current blocks

As a result, specific power outputs of approximately 55 horsepower per liter are achieved, also thanks to a supercharging system implemented with a variable geometry turbocharger. A key aspect of the Perkins “2600” series is its compliance with emission standards in highly regulated countries, primarily European and Korean Stage V, U.S. EPA Tier 4 Final, Chinese Non-road IV, and Japanese 2014 standards. The platform also supports the use of renewable fuels, such as 100% hydrotreated vegetable oils (HVO), distilled biodiesel, and standard biodiesel up to B100.

Additionally, a design approach aimed at accommodating future evolutions of emission regulations is implemented, featuring a modular architecture that can be modified without overhauling the unit. The new platform also offers telematics solutions that help improve operational management and optimize engine efficiency, reducing potential interruptions or unexpected failures.

A specific version for gen-sets

In parallel with the development of the “2600” series, Perkins also announced the launch of the Perkins “2606” engine, specifically designed for power generation. Production of this unit will begin in the second half of 2025, targeting continuous power outputs between 321 and 523 kilowatts for prime applications, and between 365 and 572 kilowatts for backup needs. The engine’s flexibility allows for easy switching between 50 and 60 Hz, thus meeting the needs of various regions and applications worldwide, making it ideal for powering data centers, industrial plants, and remote sites.

Among the various units showcased by Perkins at Eima, it is worth mentioning the four-cylinder “404J-E22Ta” with a displacement of 2.2 liters in a supercharged version aimed at agricultural machine applications at 75 horsepower, and the “904J-E36Ta” three-cylinder engines with a displacement of 3.6 liters, featuring a compact design to meet the increasingly stringent dimensional constraints of next-generation tractors.

Title: Perkins “2600” series, revolution on stage

Translation with ChatGPT