With the increasing Intensification of environmental challenges, agricultural and Industrial sectors often face prolonged droughts with severe water reserve reductions. In such conditions, innovative solutions for managing water reserves and basins are imperative, making electric pumps a key tool for optimizing the recovery and use of these resources. To address the climatic challenges of today and tomorrow, Panelli, a company based in Alessandria and part of the Pedrollo Group, introduced a new range of radial electric pumps, the “Rhx” series, during Eima 2024. These pumps represent the pinnacle of technology in their segment, capable of extracting water from great depths and delivering high flow rates, even in critical conditions.

This new series is part of a comprehensive range of electric pumps dedicated to irrigation, the company’s core business, and replaces the previous Panelli “Rx” and “Rsx” series. It sets new performance standards, offers greater reliability, and simplifies maintenance.

High-Strength Stainless Steel Construction

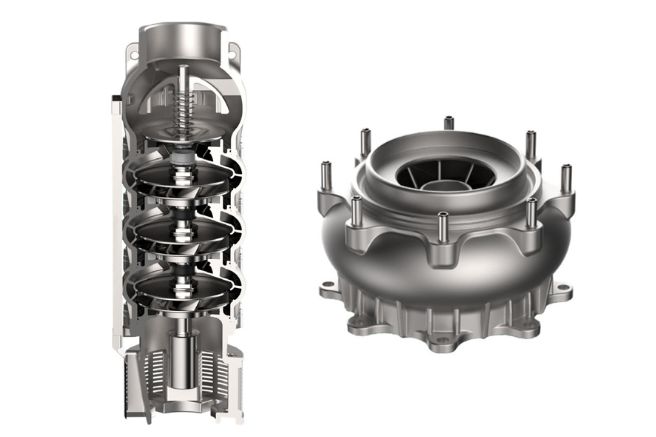

As the name “Rhx” — Radial High-Efficiency Inox — suggests, all the new pumps are made with high-strength stainless steel. They are available with hydraulic units in six-inch and eight-inch diameters and offer top-tier efficiency, exceeding 78% for the six-inch models and 75% for the eight-inch models. Thanks to their radial architecture and compact design, they can achieve head heights of up to 682 meters while maintaining a reduced footprint. They deliver flow rates of up to 50 cubic meters per hour for the six-inch models and up to 80 cubic meters per hour for the eight-inch models, operating at powers of 37 and 92 kilowatts, and pressures of 68 bar. These values refer to models powered by electrical systems operating at 50 Hz; performance increases further for 60 Hz units, which can achieve flow rates of up to 94 cubic meters per hour and pressures of up to 70 bar.

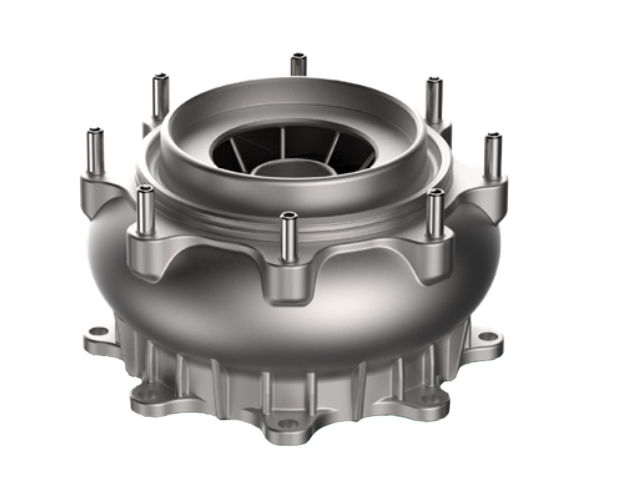

The advanced design of the “Rhx” series also optimizes hydraulic flows through a diffuser featuring a new impeller blade system, improving overall energy efficiency and increasing maximum pressure levels. The diffuser promotes laminar flow, reducing load losses and increasing internal pressure. This translates into lower energy consumption, making the “Rhx” series one of the most efficient solutions in the radial pump market.

By manufacturing all hydraulic components using investment-cast “AISI 304” stainless steel, the new series ensures high mechanical resistance.

Easy and quick maintenance

The “Rhx” series also focuses on ease of maintenance with innovative assembly solutions. The impeller is secured with a cone and ring system, eliminating the need for keyway cuts, ensuring greater shaft stability and long-term robustness. Additionally, the diffuser body fastening system, using captive screws, facilitates disassembly and maintenance, enhancing user convenience. Regarding materials, the series also includes models made of “AISI 316” stainless steel or duplex austenitic-ferritic steels, offering superior corrosion resistance even under challenging operating conditions. The units of the new series will be available globally, with a particular focus on the Italian market, where the increasing drought has spurred significant growth in the hydraulic pump sector for water recovery. European and North American markets will also play a crucial role, with the new technologies applied to the range driving substantial growth opportunities.

Title: Panelli “Rhx” series electric pumps: the pinnacle of radial technology

Translation with ChatGPT