In the field of agricultural mechanization, the development of new solutions has essentially focused for decades on material selection and improvements to structural components, aiming to achieve ever-higher performance and robustness. Only in relatively recent times have designers shifted their attention to design, and most recently, to the possibility of implementing electrical and digital management systems to enhance efficiency.

It is these latest solutions that have also allowed for rapid advancements in operational automation, bringing significant benefits in terms of work precision and operator safety. Kuhn, in particular, has moved in these directions, being long committed to electronics, digitalization, and automation through continuous investments both economically and in human resources. At Eima 2024, the latest returns from this design philosophy are represented by the newest developments in the “Optimer” disc cultivators and the Kuhn“VB 7100” variable chamber balers, which have been recognized by a jury of experts as among the most significant innovations showcased at the Bologna fair.

Precision Operations Even on Hills

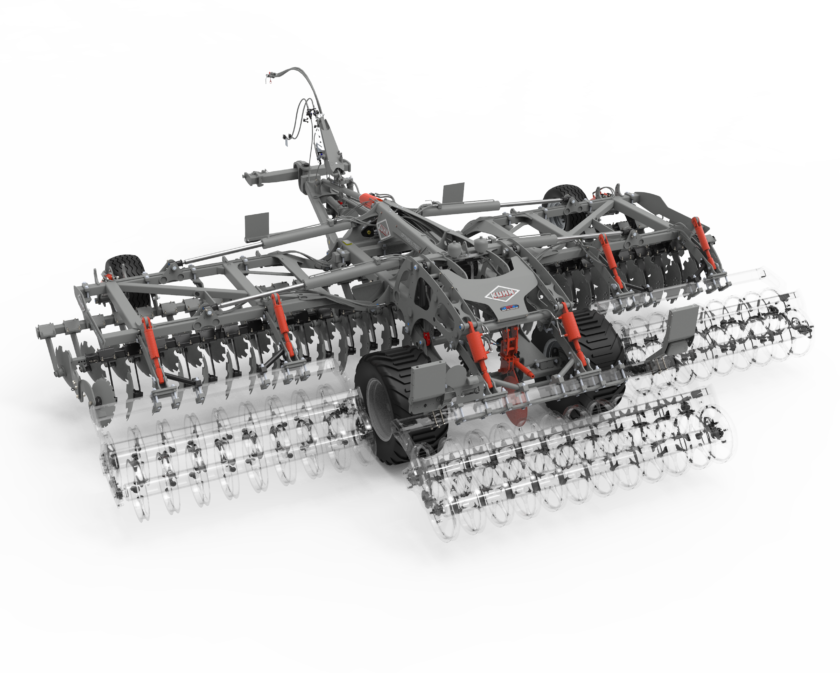

The independent disc harrows “Optimer” are typically used for the first tillage after plowing, but they can also be successfully utilized by those who wish to operate with minimal tillage. With working widths ranging from six to seven and a half meters, depending on the model, the “Optimer” series has recently been updated, allowing for some functionalities to be managed via ISOBUS protocols, such as the new “Smart Soil Technology” (SST). This solution is designed to enhance field performance while simultaneously providing greater comfort for operators through total control via a terminal in the cab.

This technological upgrade primarily benefits the uniformity of soil processing, ensured by precise mapping in terms of working depth and reduced overlaps. Additionally, there is increased hourly productivity due to the automatic headland turn management system. More specifically, the “Steady Control Ultimate” system continuously manages the working depth, adjusting the working elements across the entire width of the equipment. To achieve this, specific pressure and position sensors are connected to the onboard computer, which automatically modulates the pressure in the cylinders responsible for depth adjustment. This operational uniformity is especially advantageous on uneven terrain or at high speeds.

Ensuring correct alignment of passes in the field is the “Auto-Line” function, which continuously corrects the alignment between the cultivator and the tractor, ensuring the working area is always in line even when operating on steep slopes or when there are changes in working depth or soil type. To accomplish this, the machine has been made fully autonomous in terms of “proprioception,” the ability to perceive and recognize its position in space, thanks to a sensor on the blade that constantly measures the position of the tool relative to the forward motion. Based on the data sent by the sensor, the terminal will correct the alignment of the machine by adjusting the leveling wheels and the closing roller, thus balancing the lateral forces on the front and rear discs.

Stress-Free Balers

The series of variable chamber balers “VB 7100” has also been enriched with various functionalities that enhance productivity and comfort. Thanks to the evolution of the “Tractor Implement Management” (TIM) system, the “VB 7100” models can now automatically stop the tractor when the baling chamber has completed its work, allowing for the automatic expulsion of the bale. The cleaning of knives and the locking and unlocking functions of the power take-off in case of jams are also automatic, enabling a quick response to any issues. The “Task Controller Section Control” function autonomously manages the pickup using GPS, lowering it only when there is material to be baled on the ground, thereby reducing machine wear, especially during headland turns. Counting, weighing, registering, and mapping the bales is managed by the “Task Controller basic and geo-based” system, which also provides information about customers and the fields being worked on. All information is then transferred to Kuhn’s “EasyTransfer” system or to the company’s “Farm Management Information System,” always via “Agrirouter.” Finally, the “Auxiliary Control” displays all the functionalities of the baler and allows control via the dedicated joystick “CCI A3,” which shows all functions or can be operated using the tractor’s joystick. All operations of the “SoftKey” function buttons can also be controlled through the joystick, enabling action on the pickup, rear door, drop floor, and knives.

Title: Kuhn “Optimer” and “Vb 7100” series, innovations that reward

Translation with ChatGPT