Fixed, Trailed, or Self-Propelled: Kuhn’s TMR Mixers for Dairy Farms. Kuhn offers livestock farms a comprehensive range of feed mixers organized into three families, each designed to meet specific operational needs. At the top of the range are self-propelled mixers, particularly the twin-auger “Spw Intense” and “Spw Power” series. These models are powered by six-cylinder Volvo engines with up to 250 horsepower and John Deere engines with 170 horsepower, both Stage V compliant.

The “Spw Intense” models are available in four versions, with capacities ranging from 14 to 27 cubic meters, suitable for feeding herds of 75 to 215 dairy cows. Meanwhile, the four “Spw Power” models stand out for their compactness, remaining under three meters in height while offering capacities from 18 to 22 cubic meters. These machines cater to farms that demand high performance but require reduced dimensions.

Given their need to operate almost continuously to amortize investments quickly, Kuhn has equipped these mixers with climate-controlled, soundproofed “VisioSpace” cabins offering 20% greater visibility than standard industry designs, and integral steering systems for enhanced maneuverability in tight spaces. Efficiency is further supported by the ability to allocate hydraulic power rationally between the cutter and augers, ensuring optimal mixing of feed rations.

At the end of the mixing immediately in the trench

Once ready, rations are distributed via transverse belts controlled from the cabin, allowing precise discharge speed and positioning. This prevents contamination from foreign materials on the feed alley floors.

The same focus on ration quality is present in Kuhn’s trailed mixers, including the “Profile” series (offered with single or twin augers) and the “Euromix” series (featuring three augers). The “Profile” models, also available in “Plus” versions with straw distribution turbines, are identified by designations indicating distribution systems and tub designs. The letter “C” denotes a transverse discharge belt, “D” signifies side discharge systems, and “S” or “L” refers to narrow or wide tubs, respectively.

This results in configurations such as “Cs,” “Ds,” “Cl,” and “Dl,” offering a broad range of volumetric capacities. These range from 9–17 cubic meters in the single-auger “Profile” models, designed for farms managing up to 150 cattle, to 12–34 cubic meters in the twin-auger models, suitable for herds of up to 265 cows. At the top of the capacity spectrum are the “Euromix” models with three augers, available in “Cl” and “Dl” versions, offering tubs of 28, 33, 39, or 45 cubic meters, capable of serving farms with up to 360 dairy cows.

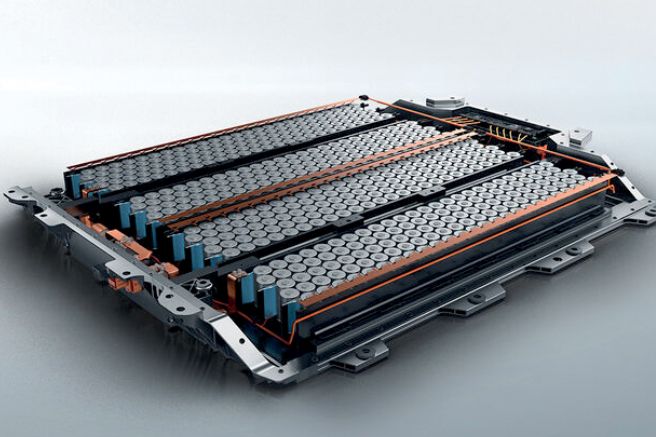

Additionally, Kuhn offers stationary mixing tubs powered by electric motors under the “CentralMix” series. These models, available in five capacities ranging from 4 to 45 cubic meters, feature motor power ratings from 18.5 to 110 kilowatts, ensuring quiet operation. Once feed rations are prepared, Kuhn provides an option for distribution using autonomous electric distribution carts, significantly reducing labor-related production costs.

Digitally Connected Machines

Kuhn has also invested heavily in digital interconnection technologies. The “Kuhn Connect” platform supports precision farming, Agriculture 4.0 concepts, and ISOBUS-compliant operations. These features are enabled through internet-connected “Cci 800” or “Cci 1200” terminals, leveraging advanced functionalities offered by the “Kuhn Cci Connect Lite” and “Kuhn Cci Connect Pro” packages. These systems aim to minimize downtime, assist operators remotely, and enable efficient data transfer.

Titolo: Kuhn cutter-mixer wagons, a question of mobility

Translation with ChatGPT