One of the reasons behind the commercial success of telescopic handlers lies in their versatility. They are machines that can perform a myriad of tasks both in the field and on the road simply by changing the attachment at the end of the arm. Until now, this operation had to be done by the operator exiting the cabin.

Time is the key factor

The mechanical connection of the attachment to the arm could be accomplished by appropriately maneuvering the machine to facilitate the attachment, but the hydraulic and electrical connections had to be done manually. This led to work interruptions that could—and still can—prolong if the connections require maintenance or even simple cleaning before being put into service. Such downtime negatively impacts productivity, and Dieci has decided to combat this by developing a system that allows for rapid attachment of equipment to a handler, making all necessary connections in a very short time and automatically, without manual intervention from the operator.

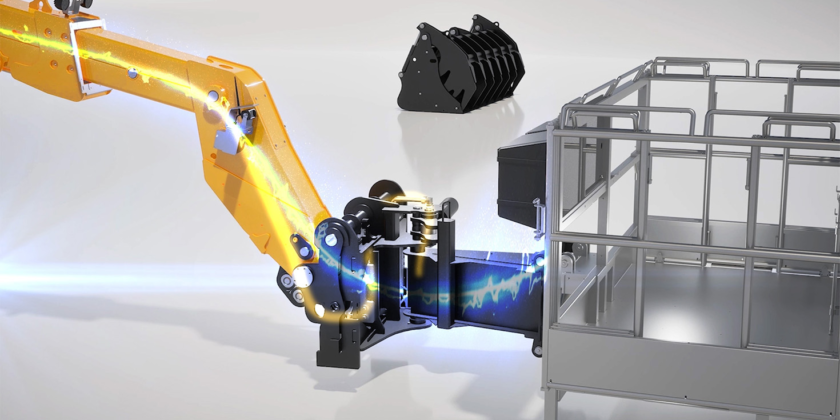

Named “Fast Attach” and awarded as a technical innovation at Eima 2024, the system essentially consists of two connectors: one installed at the end of the arm and one on the attachment. By bringing the first connector close to the second, the mechanical attachment is made first, followed immediately by the hydraulic and electrical connections. The entire process takes just ten seconds, after which the handler’s control unit recognizes the installed attachment and sets the machine’s operational parameters accordingly. The system can be installed on any attachment and any Dieci handler, even on machines already in use at various companies. In addition to speeding up work cycles, the system also enhances safety and operator comfort.

Title: “Fast Attach” system by Dieci, everything in ten seconds

Translation with ChatGPT