Cummins‘ multifuel solutions, across the board, represent a versatile and innovative approach to meeting the evolving demands of agricultural machinery and sustainability.”. At Eima International, the company showcased only engines currently in production, selecting from its extensive product lines the units best suited to represent the development trends embraced to meet the current market needs of agricultural machinery. These trends address performance and sustainability—key themes for the American brand at all its trade fair appearances—promoted through a multifuel approach centered on the development of modular engine platforms capable of accommodating a wide variety of fuels without major alterations to engine layouts. This design philosophy, defined as “fuel-agnostic,” paves the way for utilizing diverse energy carriers, initially complementing diesel with natural gas and hydrogen.

290 super eco-Friendly horsepower

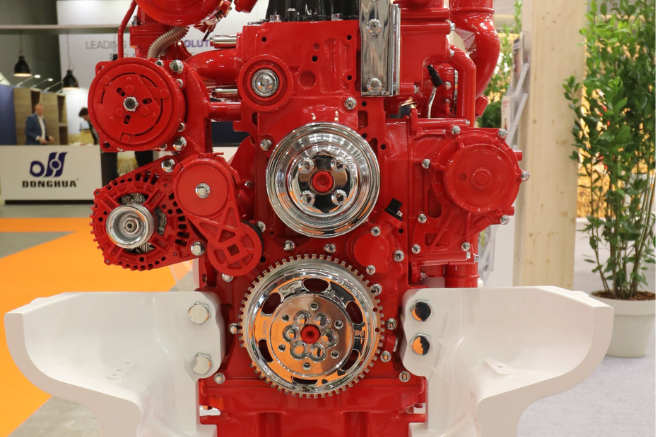

Hydrogen holds special significance for Cummins, as its production forms the foundation of one of the brand’s corporate divisions, dedicated to designing and constructing industrial electrolyzers specifically for producing this element. Cummins’ commitment to offering hydrogen-powered combustion engines was underscored at EIMA with the presentation of the “B6.7H” unit. Derived from the “B6.7” model, it has been modified to run on hydrogen. The unit, rated at 216 kilowatts (290 horsepower), can deliver up to 1,200 newton meters of torque, providing a tangible step toward decarbonizing the agricultural sector without sacrificing performance or the range of high-power machinery.

A key advantage of the engine is that it retains the engine block and some components from the diesel versions, making it easily integrable into machines currently powered by diesel-derived systems. The reuse of many diesel components from the “B6.7” version also helps reduce production costs, offering machinery manufacturers a viable option to adopt hydrogen engines without incurring the high costs typically associated with integrating battery-powered full-electric models. Alongside the “B6.7H,” Cummins also showcased the new “X15H” hydrogen units, which, with their 15-liter displacement, cover a power range of 298 to 395 kilowatts (400 to 530 horsepower) and deliver maximum torque up to 2,600 newton meters.

The “L9” for large harvesters

Also on display were traditional “F4.5” series units, which cover a power range of 90 to 120 kilowatts (120 to 160 horsepower) and deliver maximum torque of 645 newton meters. These engines are specifically designed for tractors, featuring four-cylinder blocks equipped with exhaust gas treatment systems that eliminate the need for EGR (Exhaust Gas Recirculation).

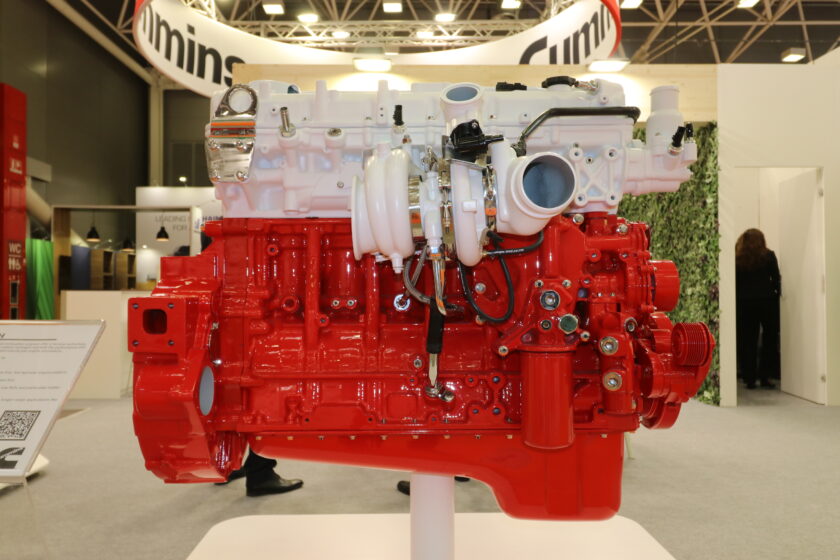

Finally, the “L9” engine in its “Harvest” version, designed for large harvesting machines, was showcased. It recently debuted in the new Claas “Trion 740” combine harvesters, with a rating of 435 horsepower at 1,900 rpm. This performance is achieved through a variable geometry turbocharger supported by optimized exhaust ducts, enhancing the engine’s responsiveness to the operator’s power demands.

Title: Cummins multifuel solutions, across the board

Translation with ChatGPT