The “Jaguar” series of self-propelled forage harvesters by Claas is the global leader in the sector, holding an impressive 50% market share. Statistically, one out of every two forage harvesters sold worldwide is a “Jaguar,” a position achieved through a combination of quality and years of consistent product upgrades.

A Boost for the “Jaguar 900”

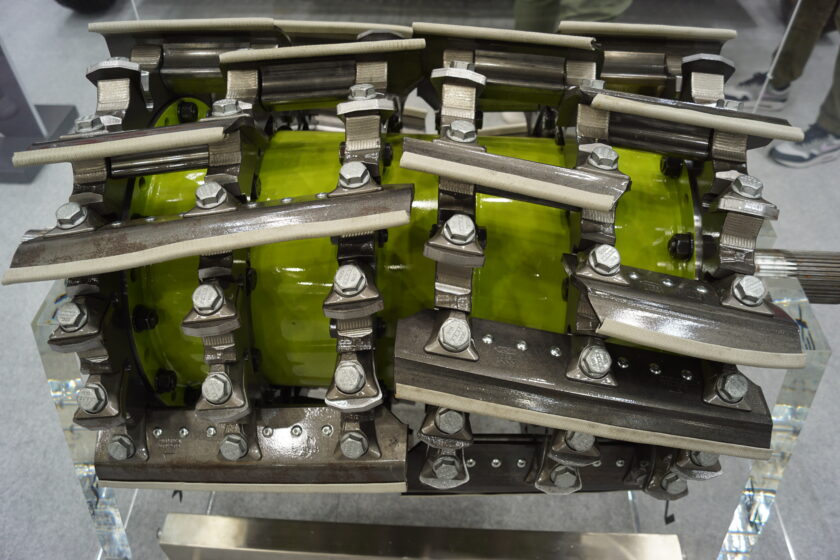

The latest advancements were introduced at EIMA 2024, featuring new “V-Flex” chopping drums across the range and the integration of “CSPS” analyses via the “Claas Connect” platform. Structurally and performance-wise, the machines remain unchanged but benefit from enhanced capabilities thanks to the new drums. While the standard drums remain “V-Classic” and “V-Max,” the “V-Flex” drum is now offered as an optional upgrade for the “Jaguar 900” and “900 Terra Trac” series. The new V-shaped design and “V-Flex” knives enable higher productivity standards.

The group also achieves lower noise levels and ensures a more uniform crop flow, especially for chopping lengths exceeding 12 mm.

Even Finer Chopping

Enhanced blade stability and triple-screw fastenings allow the blades to work closer to the counter-blade, ensuring superior chopping quality. The new drum is available in four versions—20, 24, 28, and 36 knives—and supports both full and half knives that can be alternated. It maintains an optimal 10-degree angle relative to the counter-blade, as determined by German engineers for maximum processing quality.

Guaranteed Long-Term Efficiency

The knives are coated with a wear-resistant layer, are easily replaceable in case of damage, and are available for both grass and corn. The new drums are fully compatible with Claas’s grain conditioning systems: “Multi Crop Cracker Classic,” “Max,” and “Shredlage.” Additionally, they complement the “Claas Connect” system, which will feature on 2025 Jaguar models.

The “Claas Connect” platform enables Corn Silage Processing Score (CSPS) analyses to be performed directly in the field. Previously, these analyses could only be conducted in laboratories. By placing a forage sample on a dedicated tray and photographing it with a smartphone, users can receive results within minutes from a remote lab. This allows businesses and contractors to make adjustments in real time to optimize operations and improve the final product’s quality.

New Cabins for Specialized Tractors

To expand its market share in specialized applications, Claas has introduced new four-post flat-floor cabins for its “Nexos” series tractors. The cabin interiors have been redesigned to create a more pleasant and comfortable working environment. Key enhancements include a more compact, pedal-adjustable steering column, ergonomically improved seats, and a revised control layout.

Additional upgrades include new hydraulic and electronic options and exterior design modifications, simplifying the connection of front-mounted implements.

Connected Farmers in Over 30 Countries

The “Claas Telematics” platform has evolved into “Claas Connect,” now available in over 30 countries. This platform integrates all of Claas’s digital solutions for machine management, farm operations, and precision agriculture. It also enables direct connections to maintenance services, dealerships, and digital experts to help users optimize machine performance and work processes, including activity planning and documentation.

With a single user interface, “Claas Connect” unifies machine management, operational management, and service solutions.

Spotlight on Mowers

Reinforcing its position as a global leader in forage equipment, Claas has launched four premium “Disco” mower models: “Disco 8500 C Trend,” “Disco 8500 RC Trend,” “Disco 9300 C Comfort,” and “Disco 9300 RC Comfort.” These models, named for their working widths, feature extremely robust and rigid frames with optimized centers of gravity.

Equipped with “Active Float” ground pressure regulation systems and rapid-reaction non-stop mechanical collision protection, the mowers can move tridimensionally to avoid obstacles. Additionally, the low-speed “Max Cut” cutter bar allows for operation at reduced PTO speeds, lowering fuel consumption while maintaining performance.

Title: Claas, Major and Minor Innovations for 2025

Translation with ChatGPT