Thirty years after their debut, Claas Lexion combine harvesters represent the benchmark in the sector. At the top for efficiency and productivity, they have no rivals in terms of offering, structured on the basis of four series of machines capable of responding to all the most current harvesting needs through exclusive and advanced functional solutions

The “Lexion” series combine harvesters were launched by Claas in 1995 through the “400” product line which had the privilege of christening the “Aps+Roto Plus” threshing system which in a short time became synonymous with productivity and design exclusivity. To the point of giving rise to a new category of harvesters, the so-called “hybrid”.

Characterized by an unmistakable look and always at the top of the sector for technological content and engine performance, the “Lexion” for 30 years now have always represented one of the terms of comparison in the sector, the “benchmark” to put it in English, evolving over time without ever losing its most specific and intrinsic connotations. A design philosophy to which Claas has constantly remained faithful and which it has never betrayed during the evolutionary processes to which it has subjected its top-of-the-range combine harvesters over time to create an increasingly broader and more diversified product line in terms of technical content, functionality and price/performance ratios.

Thirty years of success

Exactly thirty years after its debut, the current “Lexion” range is in fact divided into four series, labeled “8000”, “7000”, “6000” and “5000”, which, depending on the different application needs, provide both an exclusive hybrid threshing system, the “8000” and the “7000”, and a traditional secondary separation system with straw walkers, the “6000” and the “5000”. This results in a differentiation of the offer aimed at responding promptly to all harvesting needs, with the hybrid versions that, by virtue of their high performance, mainly address the needs of more structured businesses and organizations operating on behalf of third parties on large surfaces. The traditional models, on the other hand, aim to satisfy the application requests of large-scale agricultural companies that intend to combine working speed with straw protection during the harvesting phase, taking advantage of the most advanced technologies in the sector for this purpose.

This area includes the “Cemos Auto Chopping” system that equips the “Lexion 6000” and “Lexion 5000” series, a solution that continuously detects the humidity level and the quantity of straw to automatically adjust the position of the counter-blades and the friction bottom in the straw chopper based on the characteristics of the crop, thus optimising the chopping with a view to reducing consumption.

Also Aps Synflow Walker” system

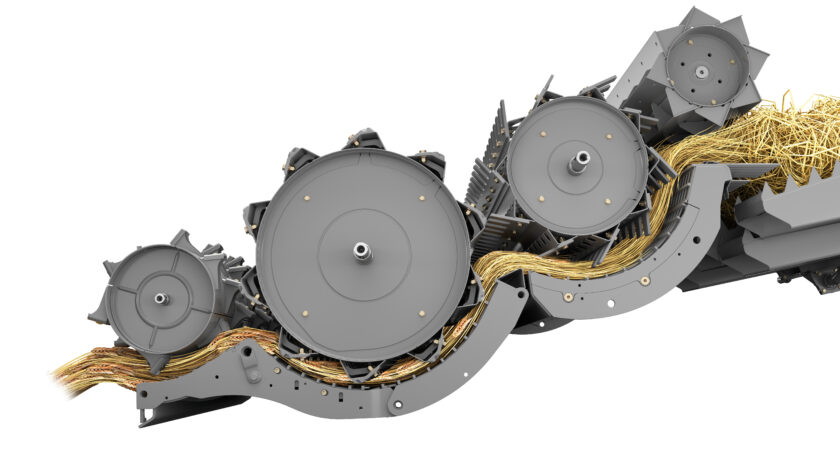

The latter can in fact be even ten percent lower than a combine harvester of the same category, without however this having a negative impact on the efficiency of the entire harvesting process, made even more effective and faster by the presence of the “Aps Synflow Walker” system, characterised by a rectilinear flow of the product and structured on the basis of a 450 mm diameter pre-accelerator, a 755 mm ten-bar beater and an additional 600 mm diameter separation cylinder placed between the beater and the launcher.

Thus structured, the “Aps Synflow Walker” system can therefore benefit from a wrap angle of 132 degrees on the beater and 116 on the additional separation cylinder, also proving easily adaptable to various types of crops and working conditions thanks to the possibility of adjusting all the separation grids from the cabin, hydraulically and in parallel. An overload protection system also prevents blockages and the counter-cave also features both blinders that can be managed electro-hydraulically from the cabin and a fold-down threshing bar to increase the friction surface and the aggressiveness towards the crop.

All solutions that in practice ensure that the “Lexion 6000” and “Lexion 5000” series separate up to approximately 25 percent more product than competing primary separation systems, while maintaining excellent straw and grain quality and effectively facilitating the secondary action of the five or six straw walkers, respectively for the “Lexion 5000” and “Lexion 6000” models, with four drop steps that provide overall separation surfaces capable of reaching six meters and 37 square centimeters in the first case and seven meters and 62 square centimeters in the second.

Engine

The optimization of the secondary separation cycle is also supported by the presence of a quantimeter that operates via an impact plate placed above the grain elevator, so as to measure in real time the yield of the harvested product before it passes into forward bins with maximum capacities of between nine thousand and 13 thousand and 500 liters.

These values are at the top of the category, which includes combine harvesters with powers of between 300 and 500 horsepower, performances delivered on the “Lexion 5000” and “Lexion 6000” series by six-cylinder Mercedes and Man engines, with the attack versions equipped with Mercedes “936” and “470” series units, respectively with seven liters and 700 cubic centimeters and ten liters and 700 cubic centimeters.

Guaranteed power

The former cover powers between 313 and 354 horsepower and are offered with dual-stage supercharging, compared to the range between 408 and 462 horsepower offered by the latter, while the top-of-the-range “Lexion 6900” version is instead equipped with a twelve-litre, 400 centimetre Man “D26” series unit set at a maximum power of 507 horsepower. In common with the flagships of the Claas range, the “Lexion 8000” and “7000” series, the Man and Mercedes engine derivations, but in this case capable of offering power settings of up to 790 horsepower delivered on the highest-performance “Lexion 8900” model by a six-cylinder, 16-litre, 200 cubic centimetre Man “D42” series unit, the same unit that also equips the “Lexion 8800” version in the maximum setting of 700 horsepower.

Also produced by Man are the six-cylinder engines of the “D26” series, 12 liters and 400 cubic centimeters calibrated at 507 and 549 horsepower that equip the high-end versions “Lexion 7600” and “Lexion 7700”, while the six-cylinder series “470” and “473”, respectively ten liters and 700 cubic centimeters and 15 liters and 600 cubic centimeters, are of Mercedes origin, which move the attack and intermediate models, making maximum calibrations available between 408 and 462 horsepower, the first, and 626 horsepower the second.

Top functionality for 30 years

Regardless of the derivation and the cubic capacity, all the units are aligned with the stage V regulations, through refrigerated EGR pre-treatment systems supported by DOC catalysts, DPF filters and SCR post-treatment systems, and interface with the work groups through belt transmissions which in turn act on reinforced variators which can be connected to the central lubrication system so as to minimize maintenance and control downtime.

Reduction in fuel consumption

Common to all engines is also the presence of the “Dynamic Power” and “Dynamic Cooling” functions, with the former adjusting the load and engine speed to the performance required by the operator with a view to reducing consumption, while the latter modulates the action of the cooling fan based on the actual thermal load, thus minimising energy absorption. The result is a reduction in fuel consumption which benefits production efficiency, an objective which is also pursued on the hybrid “Lexion 7000” and “Lexion 8000” series through the renewed “Aps” primary separation system. Renamed “Aps Synflow Hybrid”, it operates on the basis of a beater with ten 755 mm diameter bars acting on a counter-beater which integrates both blinders that can be managed from the cabin electro-hydraulically and a hydraulically folding threshing bar to increase the intensity of the treatment in the event of difficult harvesting conditions.

Characterized by a width of 1,700 millimeters, on the “Lexion 8000”, and 1,420 millimeters, on the “Lexion 7000”, the beater also offers a wrap angle of 132 degrees and is flanked by a 600 millimeter diameter launcher that fluidifies and regulates the access of the crop to the two “RotoPlus” rotors, with the latter characterized by diameters in the order of 600 millimeters and the ability to work automatically at different speeds. Thus configured, the system therefore ensures a highly effective separation process regardless of the type and conditions of the harvested product, an objective which is also achieved by the presence of the proven “Jet Stream” cleaning system, operating via a six or eight-stage turbine fan, depending on the model, and a double ventilated step to give rise to intensive pre-cleaning.

Claas lesson: safety and innovation

The system ensures a high-pressure air flow on the sieves which, like the fan, can be electrically adjusted from the cab, while the “AutoSlope” function reduces the air flow of the cleaning system when working uphill and increases it when working downhill, automatically adapting its action to the harvesting speed. In these application areas, the hybrid “Lexion” can also benefit from the “3D” function which automatically compensates for lateral slopes of up to twenty percent, while the “Cemos Automatic” system is aimed at optimising operating processes, in effect an assistant which suggests to the operator the most appropriate adjustments of the work groups based on the harvest and the conditions of the soil and which integrates the exclusive “Field Scanner” function.

The latter guides the harvester via laser along the edge of the crop to the left, right or along the advance line, transmitting the functional parameters in real time to the “Telematics” telemetry system which, by connecting the combine harvester to the company’s technical offices in real time, allows the owner of the vehicle to constantly monitor the efficiency of the work cycle in progress remotely.

A real mobile office

Designed and developed to handle intensive operating cycles, the “Lexion” range is equipped with cabins that can minimize the physical fatigue caused by long hours spent on board the machines. For this reason, the compartments feature all the most modern solutions for on-board comfort, such as, for example, pneumatically suspended seats, electrically adjustable mirrors, cameras that allow you to keep an eye on even the most difficult to see corners, refrigerated compartments for storing drinks and food and housings for tablets and smartphones.

Operational safety is also ensured by LED projectors that ensure maximum visibility of the work area, which can also be optionally integrated with supplementary lighting systems if the machines are called upon to work during the evening and night hours.

To offer the same productivity standards during harvesting on sloping terrain as are achieved on flat terrain, Claas engineers have developed two specific “Lexion” models called “Lexion 7700 Montana” and “Lexion 5500 Montana”.

the Claas “Aps Synflow Hybrid” hybrid system

The first, with 549 horsepower, introduces the Claas “Aps Synflow Hybrid” hybrid system to the hillside combine harvester sector, effectively eliminating the technological gap that has existed up to now between combine harvesters used on large flat areas and machines called upon to work on more or less steep slopes, while the second, with 408 horsepower, operates on the basis of the renewed conventional “Aps Synflow Walker” system with five straw walkers.

Common to both models are the hydraulic adjustment of the chassis which compensates for lateral slopes of up to 18 degrees and longitudinal slopes of up to six degrees, the availability of the mechanical “Power Trac” all-wheel drive system as standard or as an option, the electric locking of the front axle differential and the “AutoSlope” cleaning system which optimises the action of the cleaning system by automatically adapting it to the existing slopes and differences in level.

Maximum protection of the land

The combine harvesters that are part of the “Lexion” range are also available in the “TerraTrac” version, the track system patented by Claas for those who often and willingly operate on soft ground or on steep slopes. Eleven “TerraTrac” models in the price list, the four straw walker versions “Lexion 5500”, “Lexion 6700”, “Lexion 6800” and “Lexion 6900” and all the hybrid machines with the exception of the “Lexion 7400” attachment model, united by the ability to ensure ground pressures up to 66 percent lower than the same machine equipped in a traditional way, greater stability on slopes and minimal slippage, the latter factor that contributes to minimizing consumption. This does not, however, in any way affect the ability to travel on the road at speeds of 40 km/h and the possibility of having drive wheels on the rear axle as well.

Title: Claas Lexion: thirty-year confirmations

Translation with Google