In the field of agricultural mechanization, continuously variable gearboxes represent the mechatronic point of reference as regards power transmission. Their simplicity and immediacy of use, combined with mechanical performances increasingly similar to those offered by traditional powershift gearboxes, have made them a priority choice also by those operators who mainly use their tractors in heavy field activities and therefore until yesterday they tended to favor powershift transmissions. This is mainly due to a design approach based on an epicyclic system that progressively and continuously redistributes the driving torque supplied by the thermal engine on hydraulic or mechanical components depending on the forward speed, engine speed and load desired by the operator.

Mechanical the highest returns

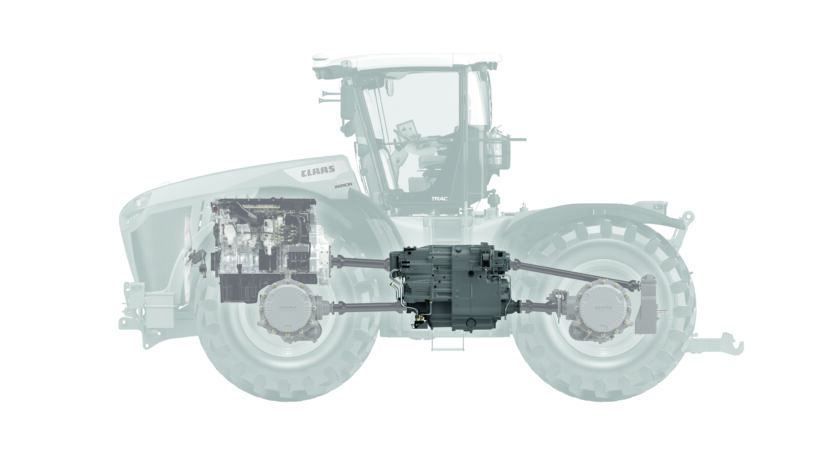

Conceived in this way, a CVT creates precise transmission ratios between the engine and the wheels, consequently optimizing the efficiency of the machine, an objective also pursued through system programming which, at the speeds most used during work, makes only the mechanical component work, a harbinger of greater efficiency than the hydraulic one. Once the driving torque has exited the gearbox, it is then distributed univocally to the wheels, in the sense that the front and rear axles are connected to each other by mechanical parts which create a fixed and predefined ratio. A solution as simple as it is for the customer, which it is no coincidence that all manufacturers offer and which Claas has even gone so far as to specialize according to the mission profile to which the various models must respond.

From 125 to 653 horsepower

The “Cmatic” range, the name with which the German brand identifies its tractors equipped with continuously variable transmissions, effectively covers a performance range that ranges between 125 and 653 horsepower, embracing five different series of tractors, each of which is oriented to very specific activities. The “Arion 500” and the “Arion 600”, the entry level series of the “Cmatic” range, are medium power open field vehicles, characterized by gross vehicle weights between five thousand 950 and seven thousand 860 kilos. , developed with a view to extreme versatility and therefore able to operate successfully also in the company in handling and maintenance activities. Depending on their mission profile, the maximum powers range between 125 and 205 horsepower delivered by four and six-cylinder engines derived from “DPS”, “Deere Power System”, which are combined with continuous transmissions of original Claas design if – rie “Eq 200” and “Eq 220”. Both groups operate through a hydrostatic system which is supported by a double epicyclic mechanical speed gearbox and a clutch group that manages its engagement, so as to effectively create a two-stage powershift.

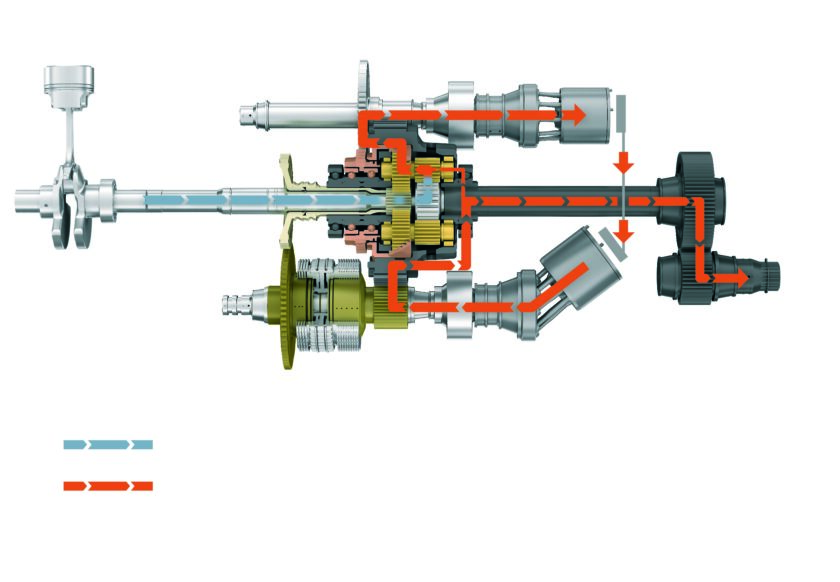

Hydrostatic ideal for accelerations

At low speeds, hydrostatic operation prevails, but this contribution gradually weakens in favor of mechanical operation as the working speed increases, until it disappears completely at the statistically most used working speeds. Upon reaching 20 kilometers per hour and in combination with various functional parameters of the engine, the transition to the second epicyclic group is obtained which relaunches the hydrostatic component by reversing the functions between pump and engine, so as to allow the tractor to advance towards higher speeds. Thanks to this, the tractor operates at the most commonly used speeds exclusively mechanically and this makes it possible to emphasize the overall efficiency by assimilating it to that of a traditional powershift transmission.

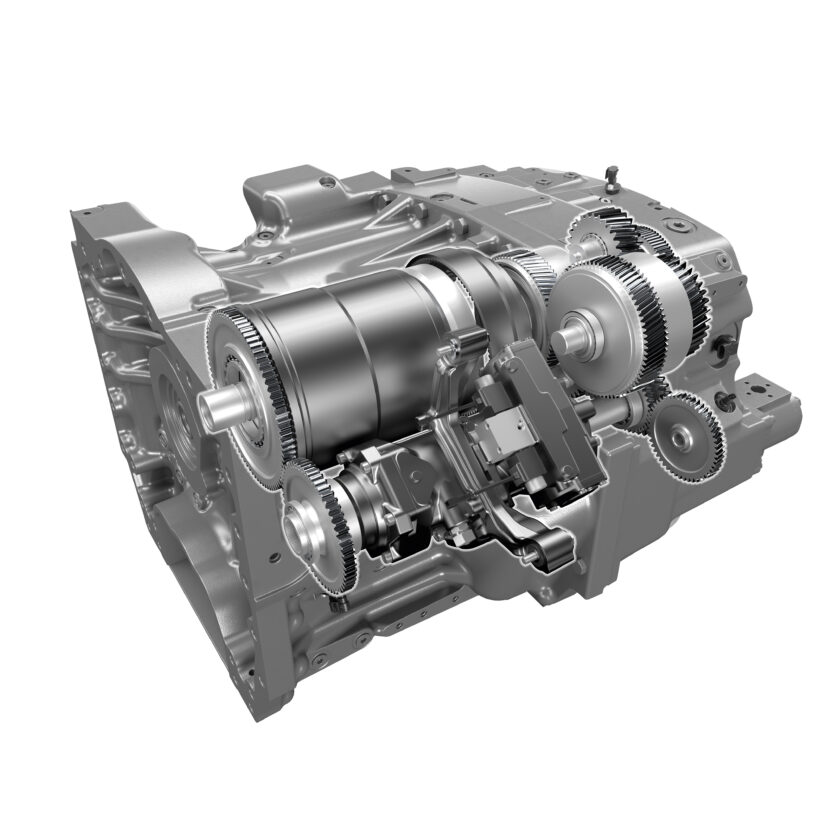

However, the concept and construction solutions underlying the continuously variable gearboxes that equip the high and very high power open-field “Axion 800” and “Axion 900” series are different, groups sharing the Zf branded production, but different in terms of versions. The “Axion 800” actually offers “Tmg25” and “Tmg28” gearboxes, while the “Axion 900” benefits from “Tmg45” transmissions, without prejudice however to the fact that both groups are conceptually similar to each other, being set on the basis of epicyclic groups which carry out the mechanical part through insertions managed by electro-hydraulic clutches which effectively simulate the action of powershifts, never lacking drive torque to the wheels during gear changes.

Always humid transients

Also in this case the mechanical ratios have been optimized by Claas technicians, in synergy with Zf engineers, so as to make them coincide with the most frequent working speeds, while a hydrostatic component then manages the working transients between one range and another in order to make the passages fluid and free from jerks. This therefore allows the “Axion 800” and “Axion 900” to always work with the minimum possible consumption depending on the activity carried out, emphasizing the flexibility of delivery offered by six-cylinder engines produced by Fpt Industrial which provide maximum settings between 205 and 295 horsepower for the “Axion 800” and between 325 and 445 horsepower for the “Axion 900″. Belonging to the ” Eccom ” series, in the ” 4.5 ” version, the continuous transmission that equips the very high power ” , and “Saddle Trac”, with a fixed cab but placed above the bonnet so as to leave the rear part of the chassis completely free for fixing boxes and tanks or for inserting a fifth wheel suitable for transforming the machine into an off-road tractor.

Structurally and performance-advanced machines that manage the range of maximum power delivered by Merced-Benz six-cylinder engines and between 458 and 509 horsepower through CVTs placed under the cab and connected to the axles via cardan shafts that are always engaged. Configured on the basis of a hydrostatic unit combined with an automatically piloted four-stage powershift, so as to create four purely mechanical speed ranges, the ” Eccom 5.5″ gearbox also operates the rear PTO, integrates a lockable differential and supports four the driving strategies, one of which is designed to keep the PTO speed constant. Finally, at the top of the “Cmatic” offer are the recent “Xerion 12″, intended for the most demanding and intensive activities based on maximum power delivered by six-cylinder Mercedes-Benz engines of between 585 and 653 horsepower. The latter performance is also linked to the need to equip the machines with transmissions also produced by Zf, but belonging to the most recent ” Eccom ” series and integrating original Claas patented auxiliary components, such as the ” Pvg ” module developed by the company Harsewinkel in the German plant in Paderborn and intended both to reduce the load on the transmission and to support the presence of hydraulic pumps for additional services with capacities of up to 537 liters per minute.

There are four mechanical ranges

Con gured in this way, the groups operate on the basis of four purely mechanical speed ranges aimed at ensuring maximum traction efficiency regardless of the activity carried out, also thanks to the presence of linear connections with the axles managed in terms of steering electronically and automatic, with the operator on board who only has to select the advancement mode deemed most congenial to the work carried out, delegating the control of the trajectories to the dedicated control unit and to the “Dymanic Steering” system which minimizes the number of steering wheel turns necessary to send the wheels from one stop to another while maneuvering and at low speed.

Title: Claas “Cmatic” range, variations on the theme

Translation with Google