Yanmar provides four propulsion units in the agromechanical segment that focus on irrigation applications and the general movement of water resources. This segment has become increasingly critical in recent years due to the challenges posed by climate change, particularly regarding the more frequent and impactful water crises affecting larger areas. In this context, pump engines represent an indispensable solution, necessary for both routine agricultural activities and emergency situations that require engines designed to operate pumping mechanisms, ensuring complete and continuous operational capacity in all environmental conditions, while minimizing maintenance intervals…

Read MoreCategory: Engines

With Cummins’ “Next Gen X15” engine a change of pace

Cummins has produced 115,000 engines in the last five years, with a portion installed in over 14,000 pieces of construction equipment. These units cover a power range from 74 to over 700 horsepower, with displacements ranging from three liters and 800 cubic centimeters to 15 liters. These performance characteristics meet the needs of manufacturers of self-propelled agricultural machinery, as they are paired with compact design mechanics, high efficiency, and considerable ease of installation. These features have been particularly pursued in the development of the power and torque curves of the…

Read MoreJcb announces the production of its millionth engine

Jcb celebrates the production of its millionth engine. Engine production began in 2004 at the Jcb Power Systems factory in Foston, Derbyshire, and expanded to India in 2010 in Ballabgarh, Delhi, with the opening of a dedicated factory. From producing three engines a day 20 years ago, Jcb today produces around 500 a day, taking on a global role in the design, development and production of diesel engines, and is now a pioneer in the development of hydrogen combustion engines. Jcb’s goal Engines produced by Jcb Power Systems have played…

Read MoreAgco Power investments, zero emissions objective

Last April the Agco group announced the launch of a 70 million euro investment plan aimed at expanding the production possibilities of the Linnavuori plant in Finland, while also increasing its research capabilities in the energy sector sustainable. With regards to the latter, the plan essentially looks at non-fossil fuels and electric motors. Production capacities will instead be increased through the creation of a new warehouse for the processing of cylinder heads and continuously variable transmission components, a new painting department and facilities for testing remanufactured engines. Also training areas…

Read MoreFpt “Xc13” engine brake, descents no problem

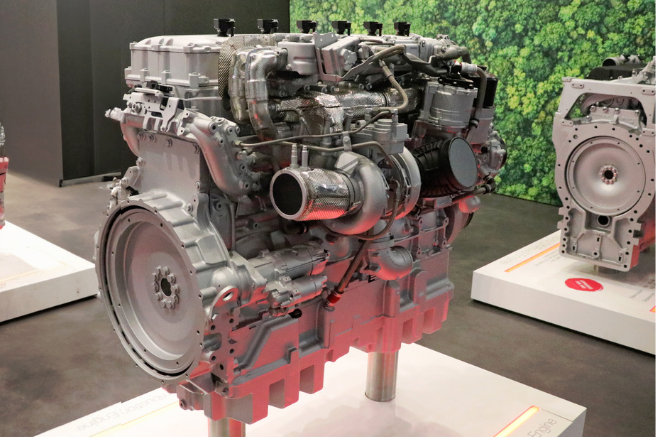

On the occasion of the presentation of the new “teardown area” Fpt Industrial took the opportunity to take stock of the latest product innovations and the most recent applied technologies. Protagonist among the “Xc13” thermal engines, the first unit that the brand has designed on the basis of new development objectives in terms of efficiency, application flexibility and power supply. Ranging between diesel, natural gas and hydrogen versions. Among the various technologies implemented on the unit, the engine braking system stands out, specific for heavy-duty applications. “High performance engine brake”,…

Read MoreYanmar range for motor pumps, also active 24 hours a day

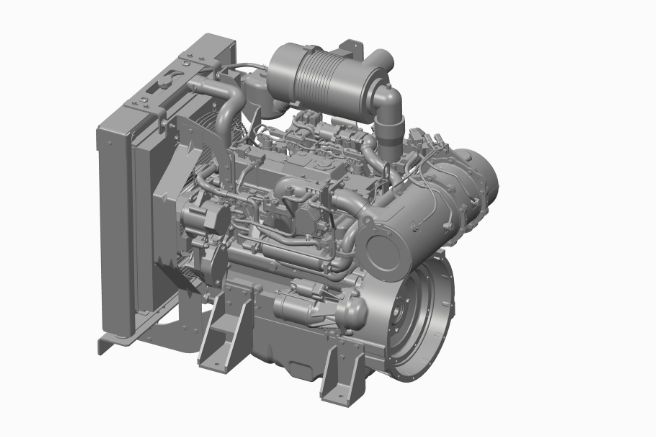

Power output ranging from approximately 25 to 70 horsepower. This is the range covered by Yanmar engines designed to power high and medium-flow pump systems for irrigation or construction, systems that, in most cases, are required to operate for long periods under variable loads and speeds, as well as in full autonomy, without constant or direct supervision by an operator. Dedicated Product Line A demanding operational profile, for which Yanmar has developed a specific product line based on four different three- and four-cylinder units, all Stage V compliant and offered…

Read MoreThe new “Engine Teardown Area” of Fpt Industrial

Three thousand square meters divided among areas dedicated to teardown benches (in Italian, the disassembly of engines for potential overhauls) and local and remote diagnostics, along with training areas. All of this is set between past and future, from an exhibition of the most important engines that have shaped the brand’s history over the past hundred years to the latest technologies in electrified systems. This is how the new “Engine Teardown Area,” created by FPT Industrial within its Turin plant, is presented: a space structured to meet the new assistance…

Read MoreReduced engine maintenance with Texaco oil

“Tact Von Eller-Ebersteinsche Bga Gbr” is the name of a mixed-type farm operating in northern Germany. In 2011, alongside traditional agricultural production, it started producing electricity from a cogeneration plant powered by a 250-kilowatt Man engine fueled with biogas. The electricity was entirely fed into the grid, while the heat from the engine’s cooling system was used to heat barns and residential buildings. In 2020, due to the positive results from energy production, the plant was expanded with the addition of a second Man engine, this time with a power…

Read MoreHeavy-duty debut

Man Truck & Bus has officially confirmed the market launch of a first series limited to 200 examples of hydrogen-powered combustion engine trucks. Units that will be operational from 2025 in Europe with some selected customers in Germany, Holland, Norway and Iceland. Man “hTgx” is the name of the new vehicles that will be equipped for heavy-duty transport. The combustion engine will be the “H45” already presented at the latest trade fairs in the industrial and off-highway segments, an engine derived from the “D38” diesel engine capable of offering up…

Read MorePerkins “5012”, top of the range for power generation

It is unlikely to find space in the agricultural sector, but secret agent 007 teaches us to “never say never,” and in any case, the machine deserves to be showcased. It is a new genset powered by a 12-cylinder engine labeled “5012,” which is at the top of both the Perkins “5000” series and the entire production range of the company. Specifically designed for power generation applications, the unit can deliver power outputs ranging from 1,275 to 1,710 kilovolt-amperes in primary generation applications at 50 hertz and from 1,250 to…

Read More