The four-cylinder, five-liter “Dx5” series units from Hyundai Infracore made their debut at Eima, and therefore in the agricultural mechanization segment. A new entry that reconfirms the growth trend in the power supplied by the 4-cylinder engines used in the tractor sector and which aligns the Korean company with the proposals already in place by Agco Power, Kubota and Volvo Penta One of the most intriguing developments in the engine sector at EIMA was the unveiling of Hyundai Infracore’s new four- and six-cylinder engines, covering a power range between 200…

Read MoreCategory: Engines

One Thousand Horsepower in Extreme Conditions

FPT Industrial has reaffirmed its position as a key player at the Dakar 2025, the 47th edition of the world’s toughest rally raid, claiming nine of the top ten positions in the final standings thanks to a CURSOR 13 engine designed to deliver one thousand horsepower and ensure outstanding performance in extreme conditions. At Dakar 2025, Iveco vehicles powered by FPT Industrial’s Cursor 13 engine swept the podium and secured nine of the top ten spots in the Truck category. As the Exclusive Technical Partner, FPT Industrial supported the de…

Read MoreDeutz Ag engines in Eima 2024: diversification objective

Deutz AG‘s presence at EIMA reaffirmed the German manufacturer’s diversification trends in response to current market challenges. The company is expanding its range of electrified solutions alongside its diesel engines and concrete hydrogen-powered offerings. At Eima, Deutz AG primarily aimed to strengthen its business in the traditional internal combustion engine segment while realigning its “green” portfolio to meet market demands for electrification and alternative fuels. This strategy, emphasized by Deutz CEO Sebastian Schulte in recent months, was reinforced at Eima with a commercial approach to electrification that shifted from providing…

Read MoreUniBo-Dig Certification | Engine comparison benchmarks

Below is an overview of the engines powering these machines and the field test results they delivered. It’s important to note that any differences between declared and actual performance stem from the fact that declared values are measured at the flywheel, while actual results are recorded at the power take-off, subject to mechanical energy losses inherent to each machine. Case IH “Puma 240 CvxDrive,” FPT Industrial “N67” The six-cylinder Fpt Industrial “N67” engines in the “Puma 240 CvxDrive” have a displacement of 6,700 cc and are among the most widely…

Read MorePerkins engine range, technologies for demanding times

The role of an engine is to generate power without taking up too much space. With these words, BU Power Systems, the official distributor of the Perkins brand, introduced at Eima the solutions from the English manufacturer dedicated to the agricultural mechanization sector. This product line has undergone significant technological advancements and updates in recent years, offering engines designed to meet the performance demands of machine manufacturers while maintaining compact packaging, reliability, low emissions, and minimal fuel consumption. The latest example of this development trend is the new “2600 Series”,…

Read MorePowerpack Yanmar, ready for anything

The Yanmar four-cylinder “4Tn101” is not a brand-new product, having been on the market for some time. However, it remains one of the most reliable and versatile engines available, a characteristic reinforced during Eima with the introduction of a “high output” powerpack configuration, calibrated to deliver 105 kilowatts of power (143 horsepower). This addition will expand Yanmar Italia’s commercial offering. Compact in size and thoroughly tested in terms of its thermal group, the engine is presented as a powerpack complete with all necessary accessories and services for operation—an autonomous energy…

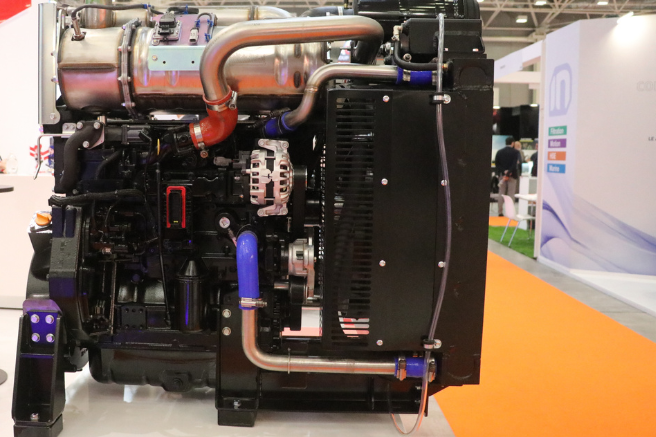

Read MoreHyundai, range expansion

The Hyundai Infracore group’s engines, a South Korean giant well-established in the earthmoving segment, are aiming to expand into the agricultural mechanization sector. Over the past few years, the company has targeted agriculture and showcased a broad range of engines at Eima this year, some of which are already integrated into the European market’s tractor segment. At the Bologna exhibition, Goldoni Keestrack’s stand displayed three- and four-cylinder “Dm” series units in the new generation of Italian-Belgian specialized tractors. These engines power Goldoni machines, with the “Dm01” three-cylinder engine featuring a…

Read MoreCummins multifuel solutions, across the board

Cummins‘ multifuel solutions, across the board, represent a versatile and innovative approach to meeting the evolving demands of agricultural machinery and sustainability.”. At Eima International, the company showcased only engines currently in production, selecting from its extensive product lines the units best suited to represent the development trends embraced to meet the current market needs of agricultural machinery. These trends address performance and sustainability—key themes for the American brand at all its trade fair appearances—promoted through a multifuel approach centered on the development of modular engine platforms capable of accommodating…

Read MoreEngine ibrid Saim, italian-japanese collaboration

Building on its partnership with the Kubota Group, established in 1991, Saim Industrial has decided to enter the electrified propulsion sector and use EIMA 2024 as the premier platform to launch its first hybrid unit. Saim was founded in 1951 with the aim of providing high-quality components to industry, particularly the automotive and marine sectors. In the engine sector, it later created the Saim Industrial division, specializing in the sale and configuration of engines for various applications; in 1991, it became the exclusive distributor of Kubota engines in Italy. Hence,…

Read MorePerkins “2600” series, revolution on stage

The engine industry is undergoing a crucial transformation phase, aimed at reducing emissions and improving energy efficiency. In this context, Perkins has introduced the development of the new “2600” series, a 13-liter platform designed to provide power density, torque, and efficiency that align with the most stringent design and operational constraints imposed by the agricultural mechanization sector, as well as more broadly by construction and industrial applications. The unit, shown for the first time at Eima 2024 and set to be included in Perkins’ offerings starting in 2026, will exhibit…

Read More