The preview last November, during Agritechnica 2023, the German agricultural mechanization exhibition. Since last July, the first models have been introduced to the market, along with the launch of an exclusive and highly advantageous commercial strategy for companies. The new Case Ih “Axial Flow 260” series combines harvesters with all the premium digital technologies in the industry, included as standard, and made available without any subscription fees. This allows operators to work with machines that fully express their functional potential without being burdened by additional production costs, aside from direct ones, while remotely viewing agronomic and machine data through the new “FieldOps” platform, which is also already available on the market.

498, 571, and 634 horsepower

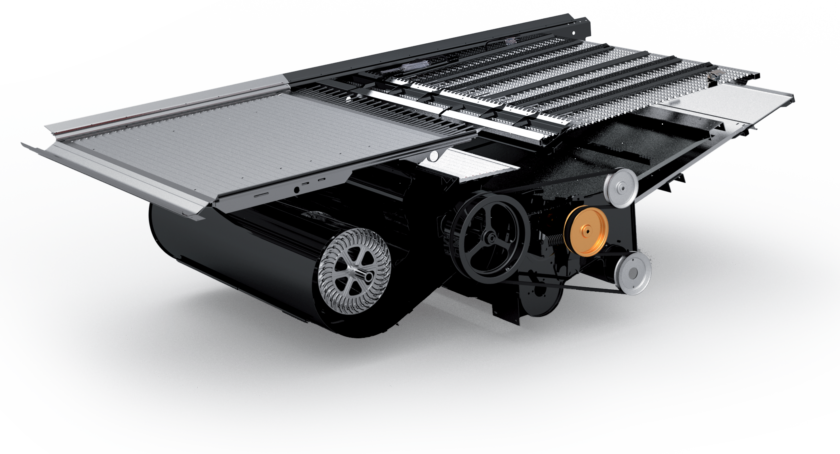

There are three available models: the “7260,” “8260,” and “9260,” with nominal power ratings of 431, 496, and 557 horsepower, respectively, and maximum outputs of 498, 571, and 634 horsepower, provided by FPT Industrial “Cursor 11,” “Cursor 13,” and “Cursor 16” engines, depending on the model. The engines interface with two-speed hydrostatic transmissions equipped with a hi-lo hydraulic shifting system, which can also be engaged while in motion, transferring torque to the ground either through all-wheel drive systems or front four-roller tracks with “ActiveTrac,” featuring hydraulic suspension that increases flotation by about 14 percent compared to fixed tracks. Regardless of the final propulsion system, the machines can benefit from the integrated automatic steering systems “RowGuide Pro” and “AccuGuide,” incorporated into the “Harvest Command” platform, which automatically manages settings to maximize yield and grain quality.

Maximum autonomy

In practical terms, these features make the new harvesters large, efficient, and user-friendly robots capable of operating almost autonomously, minimizing operator fatigue. The two large “Pro 1200” 12-inch displays in the cab contribute to this goal, offering two human-machine interfaces: one for controlling and programming the machine’s operational parameters and the other for monitoring coverage maps without switching screens. Noteworthy among the technologies available without a subscription is also the “AccuSync” app, which enables sharing work data between multiple machines in the field by connecting to other “Afs Pro700”-enabled machines present in the same field, helping to coordinate operations.

Among the machine’s additional benefits are also the high level of comfort provided by new heated and massaging seats, as well as a new climate control technology that ensures uniform air distribution throughout the cab without creating concentrated air currents. This, combined with the high acoustic and vibration insulation of the cab, the excellent visibility offered by large thermal windows, and powerful work lights, allows operators to work for long periods without experiencing physical or mental fatigue.

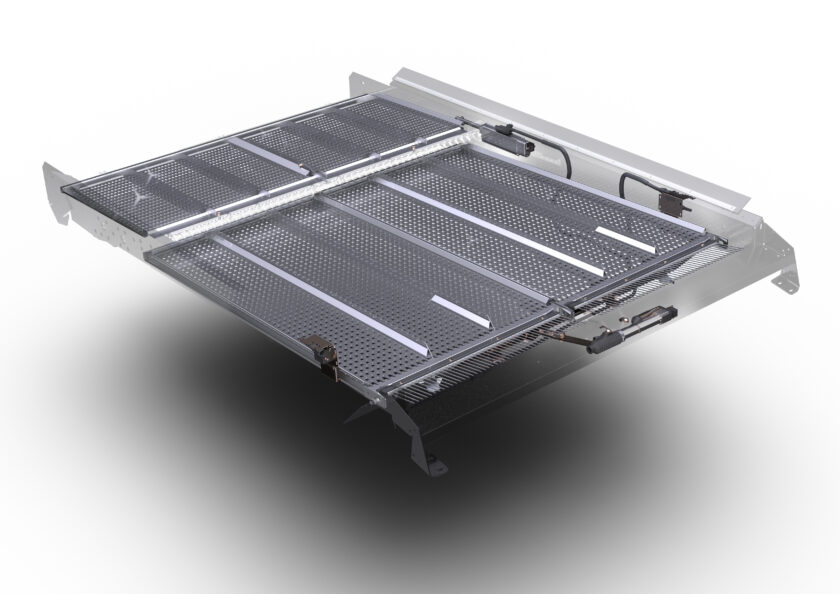

Maximum productivity is thus always ensured, as confirmed by improvements made by Case IH to its “Axial Flow” separation system and self-leveling cleaning system, which now allow for working on even larger areas in less time while also safeguarding the quality of the grain and, if required, the straw. In this context, the rotor reversal function of the “Power-Plus CVT” transmission stands out, allowing operators to clear blockages without having to leave the cab.

The new “260” series was ultimately designed to be reliable, safe, easy to operate, gentle on crops and products, and to offer the lowest total operating costs in the industry.

No extra subscriptions

Today’s farmers not only face increasing production demands, higher costs, and a shortage of skilled labor, but also increasingly complex operations to manage. Hence the need to provide them with the most advanced technologies in the industry, making them smooth and easy to use, and the consequent decision by Case Ih to launch a series of technological initiatives focused on improving the user experience for farmers. These objectives are pursued with both the presentation of the new mobile and web platform “FieldOps,” which redefines how farmers connect, view, and manage their operations, and the “Connectivity Included” philosophy, which eliminates subscription fees on this machine and simplifies the process of customizing technological needs. “FieldOps” connects and integrates agronomic and telemetry data, offering farmers a comprehensive, real-time overview of their operations, regardless of their fleet’s brand composition.

Among the main features available is the “Remote Display View” mode, which allows remote monitoring of displays to guide operators from a distance, maximizing efficiency while minimizing downtime for maintenance. This is because the dealer can connect remotely to the onboard display to check for issues and better organize service interventions. The system also provides constant updates on the location of machines in the field or on the road, allowing for better coordination and optimization of movements. It also offers a consistent and intuitive interface on mobile devices and web browsers, ensuring ease of use even on the go with a single login, and allows monitoring of crop health, growth stages, and field conditions to facilitate agronomic decisions. All of this can integrate with Case Ih equipment and third-party systems to simplify data collection and analysis, providing a holistic view of farm operations, regardless of fleet composition. Regarding the new “Connectivity Included” commercial philosophy, it should be noted that it applies to all Case IH machines built and purchased after October 1st. Those wishing to activate the same connectivity on existing machines equipped with compatible telematics modems and a Case IH “FieldOps” account (previously known as “Afs Connect”) can do so by paying a one-time fee and contacting their dealer. They, too, will then have unlimited and free access to agronomic data, advanced telemetry, and proactive dealer support for years, helping to minimize potential issues and downtime.

Title: Case Ih “Axial Flow 260” Combine Harvester, Free Automation

Translation with ChatGPT