Agricultural and livestock companies normally dedicate the winter season to maintenance of machines and equipment. Among the essential interventions are those relating to the undercarriages of trailers whose basic components, brakes, bearings and bushings, if worn or malfunctioning, can give rise to very dangerous situations. And the Adr Axles spare parts platform is a guarantee

Dedicated to all operators in the agricultural and livestock sectors, the Adr Axles spare parts platoform. According to industry research, farmers and breeders spend approximately one hour per day on machinery maintenance. This time frame represents an average between routine inspections carried out during work periods and more intensive full-time maintenance focused on replacing worn-out or faulty parts. While unforeseen repairs can arise throughout the year, most major maintenance work takes place in the winter months, when fields are at rest. This period allows time for more complex interventions, such as axle and suspension maintenance—fundamental procedures to ensure optimal trailer performance and safe operation in the field.

Preventive Maintenance: Reducing Downtime and Enhancing Safety

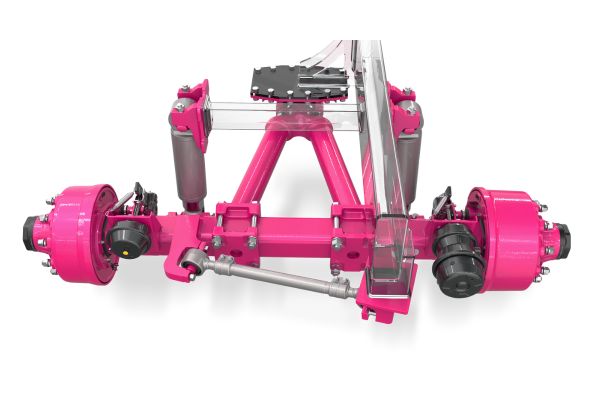

Implementing a preventive maintenance plan helps eliminate the risk of sudden breakdowns, extends the lifespan of agricultural machinery, and prevents downtime that could disrupt farming activities. Since axles and suspensions are crucial components of trailer undercarriages, their deterioration can compromise trailer stability. This can lead to dangerous situations, especially when towing at maximum road speeds permitted by law.

Therefore, it is essential to inspect key components, including:

- Bearings and hub seals

- Brake components subject to friction

- Bushings and suspension joints

- If the suspension system is hydraulic, also check the actuation system

Since these are complex interventions, they are best entrusted to specialized technicians. Furthermore, all worn or broken parts should be replaced exclusively with original spare parts, such as those available on the ADR Group’s advanced spare parts platform.

Adr Axles spare parts platform: Simplifying Maintenance Management

Adr’s platform streamlines periodic maintenance, making it easier to purchase spare parts for axles, suspensions, and brakes while ensuring error-free and precise orders. The system enables users to:

✅ Identify and order the correct spare parts for each component

✅ Ensure compatibility with the specific machinery

✅ Access pre-packaged kits containing all necessary components for successful repairs

✅ Reduce delivery times, with emergency shipments available 24/7 (“H24”)

Adr’s Innovation: Lubrication-Free Suspensions & TeknoAx RFID App

ADR Group has always prioritized reducing maintenance requirements for its products. In this regard, the company offers Lubrication-Free suspensions, which eliminate the need for periodic greasing.

Additionally, ADR has developed the TeknoAx RFID app, allowing users to scan the product code and production order using a smartphone. This provides direct access to after-sales support services, ensuring quick and efficient maintenance management.

Title: Adr Axles spare parts platform: prevention so you don’t have to cure

Translation with ChatGPT